What Are You Looking For?

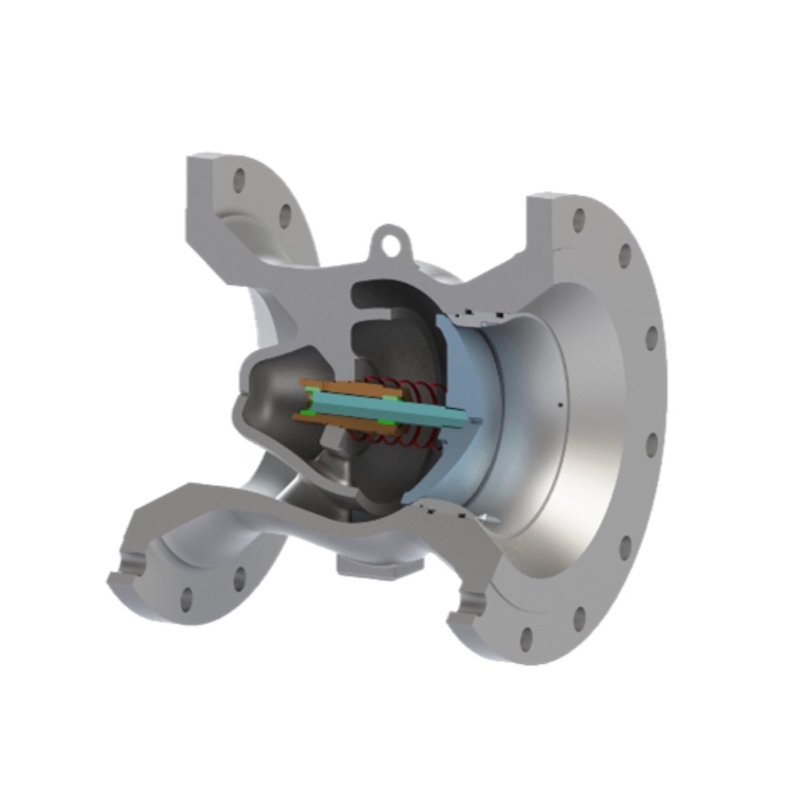

The GKV525 Axial Flow Check Valve, also known as a non-slam check valve or axial non-return valve, is engineered to allow flow in one direction and prevent reverse flow that can cause water hammer or pressure surges.

Its spring-loaded axial design ensures fast, smooth closure without slamming, providing superior protection for pumps, compressors, and pipelines. Designed with a Venturi-style body, it delivers low pressure drop, high reliability, and silent operation in demanding applications such as oil & gas, power, chemical, and water industries.

|

GEKO Axial Flow Check Valve – Non-Slam, Fast Response & Water Hammer Protection

|

|

|

Size Range DN25 – DN1200 (1" – 48"), larger sizes available upon request |

Body Material WCB, A350 LF2, CF8 / CF8M (304 / 316), Duplex, Super Duplex, Hastelloy, Alloy 20, Ductile Iron, Forged Steel |

|

Temperature Range -196°C to +600°C (depending on materials and seal type) |

Pressure Rating ANSI / ASME Class 150 – 2500, PN10 – PN420 |

|

Flow Direction One-way flow (automatic closure against reverse flow) |

Seat Material Metal-to-Metal (SS, Monel, Inconel) or Soft Seated (PTFE, RTFE, PEEK, Elastomers) |

|

Disc / Obturator Single low-mass disc, spring-loaded axial movement, optional hard-faced sealing surface |

Spring & Shaft Material 17-7PH, Inconel X-750, 316SS, Alloy Steel, corrosion and fatigue resistant |

|

Bolting / Fasteners ASTM A193 B7 / B8 / B8M / B16, Inconel or Alloy Steel as per service condition |

Sealing & Gasket Graphite, PTFE, Spiral Wound or RTJ Metal Gaskets depending on temperature and pressure |

|

Design Standards ASME B16.34, API 6D, ISO 14313, EN 593, API 598, EN 12266-1, ISO 5208 |

Inspection & Testing Pressure, Seat Leakage & Functional Tests per API 598 / ISO 5208 |

|

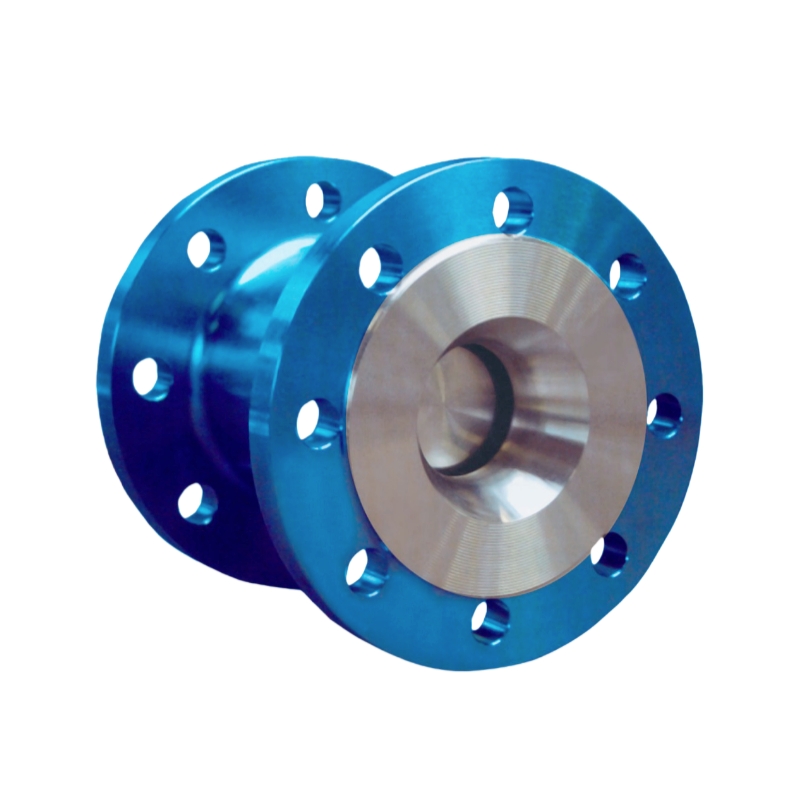

End Connection Standards Flanged: ASME B16.5 / B16.47 / EN 1092 |

Design Type Venturi design, spring-assisted axial movement, short stroke non-slam configuration |

|

Special Design Features Non-slam closure, low pressure drop, venturi flow path, fast response time, minimized water hammer, maintenance-free construction |

Optional Design / Structure Long / short pattern, removable internals, dual-seal configuration, position indicator, damping system, anti-surge trim |

|

Operation Method Fully automatic (spring-loaded self-closing) |

Surface Protection Epoxy coating, polymer lining, nickel plating, or thermal spray (WC-Co) for anti-corrosion service |

|

Applicable Standards & Certificates MTC EN10204 3.1 / 3.2, NACE MR0175 / ISO 15156, Third-party inspection (DNV, BV, LR) |

Applications Oil & Gas, Petrochemical, Power Generation, Water Systems, Chemical Processing, Steam, Compressor Discharge, Fire Water Lines |

|

Cracking Pressure Adjustable: typically 0.02 – 0.5 bar, depending on spring selection and system design |

Maintenance No routine maintenance required; inline replaceable internals optional for heavy-duty applications |

|

Packaging & Delivery Anti-corrosion oil, flange protectors, export-grade wooden box or pallet packaging |

Key Highlights Fast-acting non-slam closure, water hammer protection, low pressure drop, compact & robust design, high reliability under dynamic conditions |

Design Standards of GEKO GEKO Axial Flow Check Valve:

ASME B16.34 – Pressure & temperature ratings, materials, testing

ASME B16.10 – Valve face-to-face dimensions

API 598 / EN 12266 / ISO 5208 – Valve testing and leakage standards

API 6D / ISO 14313 – Pipeline valve design and manufacturing

Available Materials:

Carbon Steel / Stainless Steel / Low Temperature Steel

Alloy & Special Steel (e.g., Hastelloy, Duplex) / Ductile Iron

Forged or Cast Construction

End Connections: Flanged (standard) / Wafer type or butt-weld (optional)

Typical Pressure Ratings: ANSI Class 150 – 2500 (PN 10 – PN 420)

Size Range: DN 50 to DN 1200 (2” to 48”)

Product Features – Advantages & Benefits

Non-Slam Design

Eliminates water hammer and pressure surges through rapid, smooth closure.

Axial Flow & Body

Provides optimized flow with extremely low pressure drop and high energy efficiency.

Spring-Loaded Disc Mechanism

Ensures instant response and stable operation under varying flow conditions.

Compact, Lightweight Construction

Available in long or short pattern types for flexible installation.

Metal-to-Metal Seating

Guarantees long service life, excellent sealing, and zero maintenance.

High Reliability

Designed for continuous operation in critical applications such as

compressors,pumps, and turbines.

Excellent Hydraulic Performance

Even flow distribution and minimized turbulence for superior system stability.

Corrosion & Surface Protection

High-grade coatings for durability in harsh industrial environments.