What Are You Looking For?

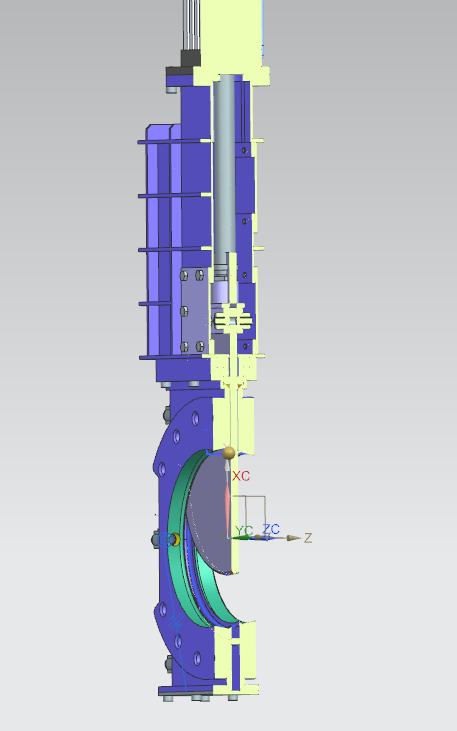

GEKO's latest design, the new knife gate valve with blowout holes, is capable of handling high-speed flow, high viscosity, and media containing particulates. This innovation significantly extends the valve's service life, particularly due to its blowout holes and bottom component design, which also makes maintenance much more convenient.

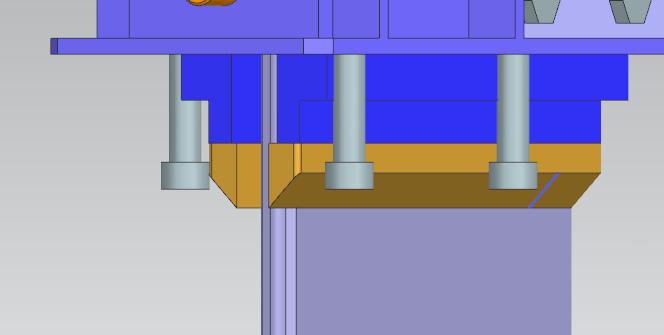

I.Built-in Scraper at Packing:

The built-in scraper at the packing primarily enhances sealing performance, reduces leakage, extends valve service life, ensures structural stability, and facilitates easy processing and installation.

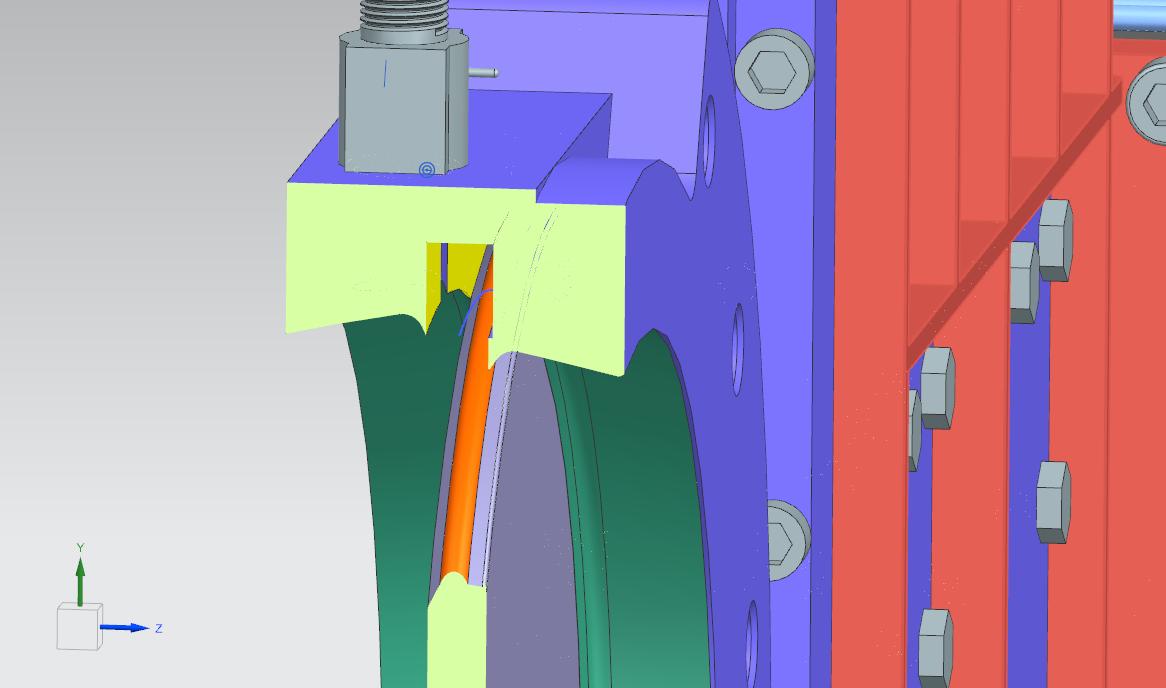

1. The design of the built-in scraper at the packing of the knife gate valve effectively improves the sealing performance by incorporating a scraper within the packing. This design leverages the physical characteristics of the scraper, such as an arc-shaped inclined surface that closely adheres to the valve body and extends along the valve plate, and a C-shaped cross-section fixed by the knife seat. This makes the overall structure easy to process and install while maintaining structural stability and resistance to deformation over prolonged use. Such a design maintains consistent cleaning efficacy, thereby reducing leakage and enhancing equipment operational efficiency.

.

.

Additionally, the built-in scraper exhibits strong wear resistance, with the sealing surfaces of the knife plate and base made from hard materials. It can handle high-speed flow, high viscosity, and media containing particulates. When dealing with particulate-laden media, the wear-resistant materials of the scraper help to reduce wear and leakage issues, thereby increasing the reliability of the valve.

Dual-Sided Scraper Design of the Valve Plate:

Enhanced Sealing Performance: The knife gate valve boasts excellent sealing performance, with gaskets made from either metal or elastic materials to effectively prevent media leakage. This design ensures a significant improvement in the sealing performance between the valve plate and the seat during opening and closing operations, thereby reducing the likelihood of media leakage.

High Adaptability: The knife gate valve exhibits good wear resistance, with both the valve plate and the base's sealing surfaces made from hard materials. This allows the valve to handle high-speed flow, high viscosity, and media containing particulates. This design makes the knife gate valve more reliable when dealing with particulate-laden media, reducing wear and leakage issues

Extended Service Life: The knife gate valve design considers factors that extend its service life. For example, the bottom end of the valve plate is processed into a blade shape, which can cut through soft materials while ensuring smooth opening and closing. Additionally, a hard PTFE scraper is installed at the upper end of the valve plate to prevent abrasive substances such as dust and gravel from entering the packing box, significantly improving the lifespan of the valve plate.

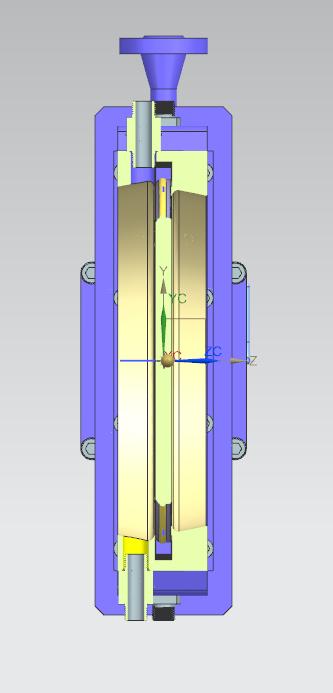

3. Unique Design Compatible with Both Hard Sealing and Soft Sealing Structures

The advantage of having both hard and soft seals in a knife gate valve lies in the flexibility and adaptability it offers, allowing the valve to meet different operational environments and sealing requirements.

By integrating both hard and soft seals in the same valve, users can choose according to specific operational conditions and requirements. For instance, in situations demanding high wear resistance and high-temperature performance, a hard seal is preferred; whereas in cost-sensitive applications or those requiring frequent seal replacements, a soft seal is more suitable. This design provides greater flexibility, enabling the valve to adapt to various working conditions while maintaining excellent sealing performance and lower costs.

Additionally, this design can extend the valve's service life to a certain extent. Since hard and soft seals each have their own service life, a compatible design can balance the usage of both, thereby prolonging the overall service life of the valve.

Contact us: info@geko-union.com