What Are You Looking For?

GKV655 Cage Type Plug Valve Anti-Static and Fireproof are available in four different patterns. The pattern indicated basic information about the valve in terms of end dimension (according to API 6D, BS 5353, ANSI B16.10 and DIN 3202/F1) & the size of the flow port through the valve. Various ports can be designed, quick turn on-off operation, easy to maintain, minimal resistance to flow, anti-static and fireproof design.

|

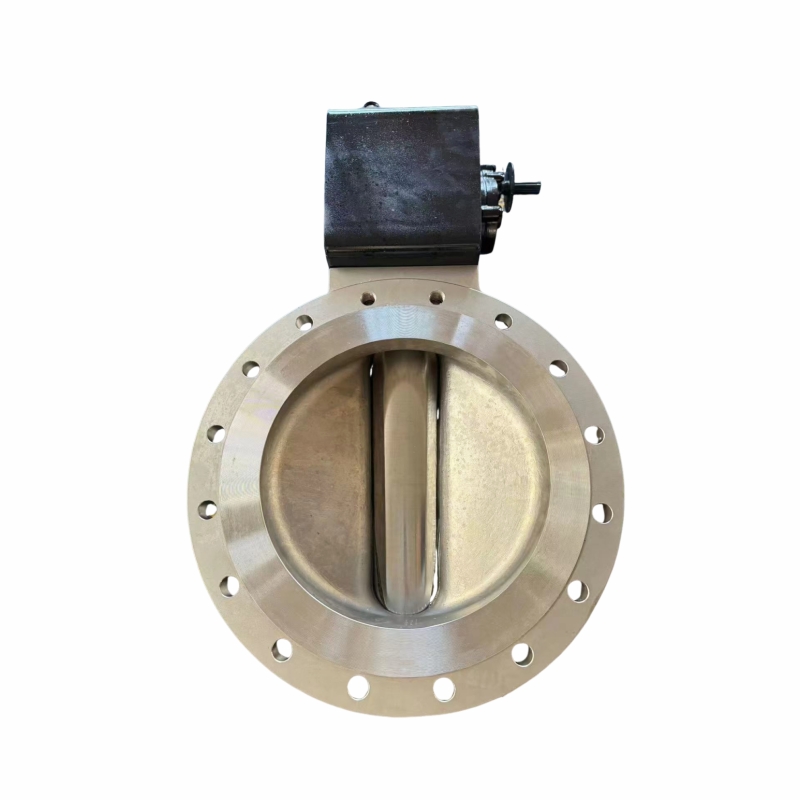

GKV Cage Type Plug Valve Anti-Static and Fireproof

|

|

|

Size Range NPS 1/2" to 12" (DN15 to DN300), larger sizes up to DN600 available upon request |

Body Material Options Carbon Steel (WCB), Stainless Steel (CF8, CF8M, CF3, CF3M), Duplex Stainless Steel (4A/5A), Alloy 20, Hastelloy®, Monel®, Inconel®, Titanium |

|

Temperature Range -50°F to +650°F (-46°C to +343°C), extended ranges available with special alloys |

Stem / Shaft Material ASTM A479 Gr. 316, optional 17-4PH, Duplex SS, low-friction coating available |

|

Maximum Allowable Working Pressure ASME Class 150 & 300, PN16, PN25, PN40 |

Seats & Seals RPTFE, TFM1600, Tek-Fil®, PEEK, UHMWPE, Metal-to-Metal |

|

Plug Material ASTM A351 Gr. CF8M, optional hardfaced/coated (ENP, Stellite®, Cr-Carbide) |

Shutoff Rating Class VI, bubble-tight shutoff optional |

|

Operation Method Lever, Gear Operator, Pneumatic Actuator, Electric Actuator, ISO 5211 platform |

Body Style & Ports 2-Way (Straight), 3-Way (L- or T-pattern), Full Bore or Reduced Bore |

|

Design Standards ASME B16.34, API 608, MSS-SP-72 |

End Connection Standards Flanged: ASME B16.5 (RF/RTJ), DIN EN1092 PN16/25/40 |

|

Testing & Inspection API 598, ISO 5208 Pressure & Leakage Test Optional NDT: Radiography, Ultrasonic, Magnetic Particle |

Face-to-Face Dimensions ASME B16.10, ISO 5752

|

|

Special Design Features Bi-directional sealing, low operating torque, multiple seat options, full-bore flow, modular actuation, corrosion & wear resistance, long service life |

Applications Oil & Gas pipelines, Petrochemical processing, Fuel handling systems, Municipal water & wastewater, Chemical plants, Power generation |

Short Pattern

Compact face-to-face dimensions, similar to a gate valve.

Port area: 40–50% of a full-bore plug valve.

Suitable for applications where some reduction in flow rate is acceptable.

Available in Class 150 and 300.

Regular Pattern

Longer face-to-face dimensions.

Port area: approximately 50% of full bore.

Provides minimal flow loss while optimizing overall valve dimensions using a rectangular port.

Available in Class 600 and 900.

Fire Safety

Sleeved plug valves can be supplied in a fire-safe design according to API 607.

Anti-Static Design

Static electricity can build up around the plug due to current in the line or friction

between the plug and PTFE sleeve.

Anti-static version: a conductive ring is inserted into a groove in the adjusting

screw, creating an electrical connection between the plug and the valve body to

safely dissipate static charge.

Purge Connections

Valve bodies can be supplied with one or two purge connections, allowing the

interior of the valve to be cleaned when required.

Cavity Relief

Valves can be equipped with a relief hole or slot in the plug.

This feature is required for services that cause pressure build-up or

polymerization when the valve is closed.

Unique design of GEKO plug valve series

Body Design

- The PTFE sleeve serves as the seat for the valve plug, eliminating metal-to-metal contact.

- Low turning effort and galling prevention are achieved, allowing use of any body/plug material combination.

- Positive shut-off is ensured, and valves are virtually maintenance-free.

- PTFE flow under temperature and pressure is prevented by containment lips cast around the body ports. These lips also prevent rotation of the sleeve during operation.

Sealing and Performance

- High performance is achieved through intimate contact between the plug and firmly fixed PTFE sleeve, along with separate atmospheric seals.

- The primary seal to atmosphere is provided by the PTFE seat. Even after long-term service and seat wear, GEKO valves maintain effective atmospheric sealing.

- Cover flange sealing uses a PTFE diaphragm protected by a metal diaphragm, with an additional PTFE ring and a Delta ring to prevent stem leakage.

Sleeve Damage Protection

- GEKO valves feature a special mechanism ensuring total atmospheric sealing

even if the sleeve is damaged.

- In cases of severe sleeve damage, the taper plug can be adjusted to uniformly

compress the PTFE filament packing, which is held between two thrust rings.

- By tightening the adjusting screw, a shoulder on the thrust ring is pulled down

against a lip in the cover, compressing the packing for complete sealing under severe

conditions.

Operating Torque and Packing

- GEKO plug valves provide bubble-tight sealing with low operating torque.

- Semi "-2" size models feature internal pre-tightening of the packing using

GEKO’s unique process technology.

- 2/2 "-12" size models use a separate packing cover, easily adjustable without

disassembly or removing actuators, with a design that evenly distributes load on

the packing.

Optional Hard Coating – Stellite®

- Valve seats can be coated with Stellite® cobalt-chromium alloy, offering:

- Excellent corrosion resistance

- High working temperature capability

- High hardness for superior wear resistance

GEKO Cage-Type Plug Valve with PTFE Sleeve Protection Application