What Are You Looking For?

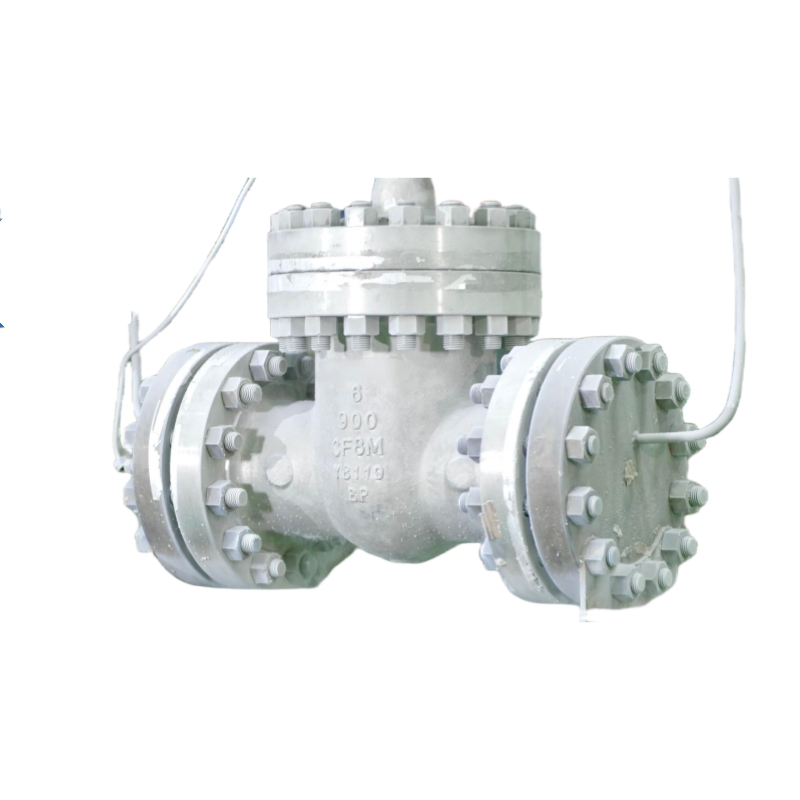

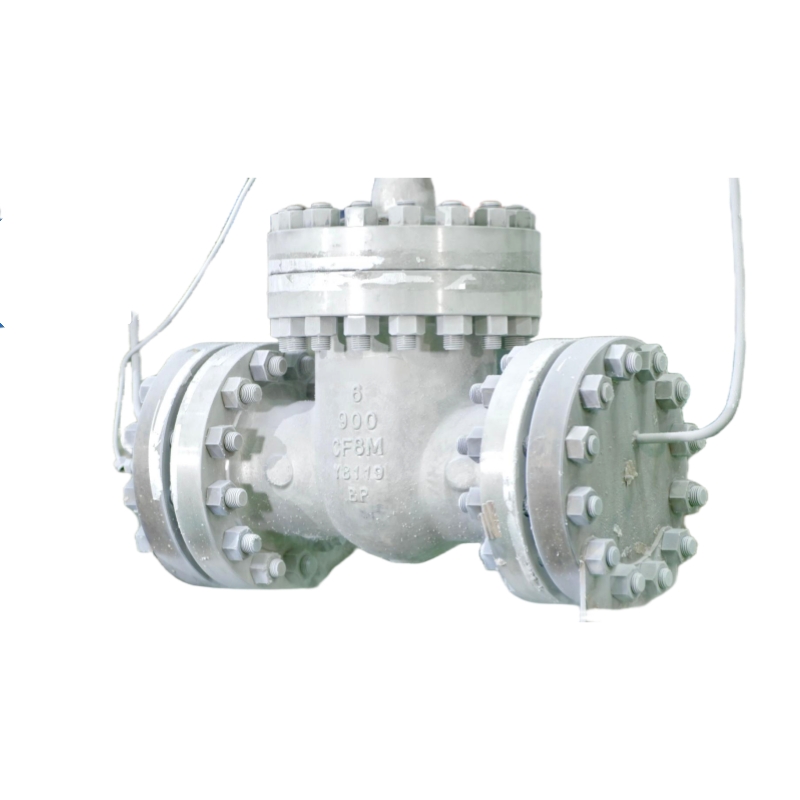

GKV426L GEKO Cryogenic Gate Valve with smooth operation, minimal thermal expansion, and robust construction. Reliable sealing, low operating torque, and long service life make it ideal for LNG, industrial gases, and cryogenic chemical applications.

|

GKV Cryogenic Gate Valve – Smooth Operation, Low Torque & Long-Life Performance

|

|

|

Size range 1/2" ~ 42" (DN15 ~ DN1050) |

Body & Bonnet Material A350 LF2, LCB, LC3, CF8, CF8M (304L/316L), CF3, CF3M |

|

Temperature range -196°C to +50°C (-321°F to +122°F) |

Stem / Shaft Material 304 / 316 / CF8M stainless steel, optional low-friction coating |

|

Maximum Allowable Working Pressure ANSI / ASME Class 150 – 2500 (depends on size and material) |

Seats & Seals Cryogenic-grade PEEK, PTFE, PCTFE, or metal-to-metal seals |

|

Stem Material 304 / 316 / CF8M stainless steel, optionally hardened or coated |

Packing & Gland PTFE / graphite composite, low-temperature resistant |

|

Special / Optional Materials Super Duplex, Inconel, Monel, special cryogenic alloys for corrosive fluids or extreme low temperatures |

Operation Method Manual (Handwheel / Gear), Pneumatic, Electric Actuated

|

|

Special Design Features Smooth gate operation, minimal thermal expansion, low torque, robust structure, anti-frost/thermal shock resistant, modular/lightweight |

End Connection Standards Flanged: ASME B16.5 / EN1092 |

|

Design Standards ASME B16.34, API 600, BS 6364 / ISO 14313

|

Applications LNG storage, transfer, industrial and specialty gas pipelines, cryogenic chemical processing, low-temperature fluid control |

|

Testing & Inspection Pressure & Leakage Test: API 598 / ISO 5208 |

Key Highlights Leak-tight at -196°C, long service life, low maintenance, low operating torque, safe for cryogenic fluids, modular & lightweight

|

Technical Specifications:

Size Range: 1/2" ~ 42" (DN15 ~ DN1050)

Pressure Ratings: ASME Class 150 ~ 2500 (PN16 ~ PN250)

Body Materials: Stainless Steel ,304L, 316L, CF8, CF8M,

A350 LF2, LCB, LCC,Monel,Inconel, Hastelloy, Duplex SS

End Connections: RF, BW, RTJ

Seat: PTFE, PCTFE

Minimum Design Temperature: -196°C

Certified: Complies with API, ISO, and ASME standards

Reliable: Tight shut-off, precise flow at ultra-low temperatures

Durable: Stainless or alloy steel with cryogenic treatment

Sealed: Metal seats for leak-tight operation

Flexible: Manual, electric, or pneumatic actuation

Advanced Technology :

Super Low Torque Design – Optimized gate guide reduces operating effort.

Enhanced Cryogenic Sealing – Zero-leak performance at -196°C.

Minimal Thermal Expansion – Maintains dimensional stability and sealing integrity.

Anti-Frost & Thermal Shock Resistant – Protects components from low-temperature stress.

Smart Monitoring Integration – Optional remote sensors for operational status, pressure, and temperature.

Lightweight, Modular Design – Simplifies installation and maintenance.

Fire-Safe & Anti-Static Compliance – Ensures safety in LNG and combustible gas applications.

Advanced low-temperature testing facilities

Facilities are managed by experienced low-temperature valve specialists.

Low-temperature test pit for large valves

6,000-gallon liquid nitrogen tank for extreme cooling

Mass spectrometer for precise leak detection

Capabilities enable performance validation, design optimization, and tailored testing solutions for critical cryogenic applications.

Structure:

Smooth Gate Operation – Ensures precise and effortless flow control.

Minimal Thermal Expansion – Maintains performance under extreme cryogenic conditions.

Robust Construction – Durable design for long-term reliability.

Reliable Sealing – Leak-tight performance, reducing risk and maintenance.

Low Operating Torque – Easier operation and safer handling.

High Cryogenic Stability – Stable performance at very low temperatures.

Extended Service Life – Reduces replacement costs and downtime.

Storage tanks, transfer pipelines, liquefaction/regasification facilities, and loading/unloading stations.

Liquid oxygen, nitrogen, argon pipelines, high-purity gas distribution, and cryogenic storage applications.

Low-temperature chemical storage, cryogenic reaction vessels, and safe isolation of hazardous fluids.

Cryogenic fuel storage, supercooled liquid handling, and LNG-fueled power plants.

Low-temperature laboratories, superconducting systems, space/aerospace cryogenic fuel control.