What Are You Looking For?

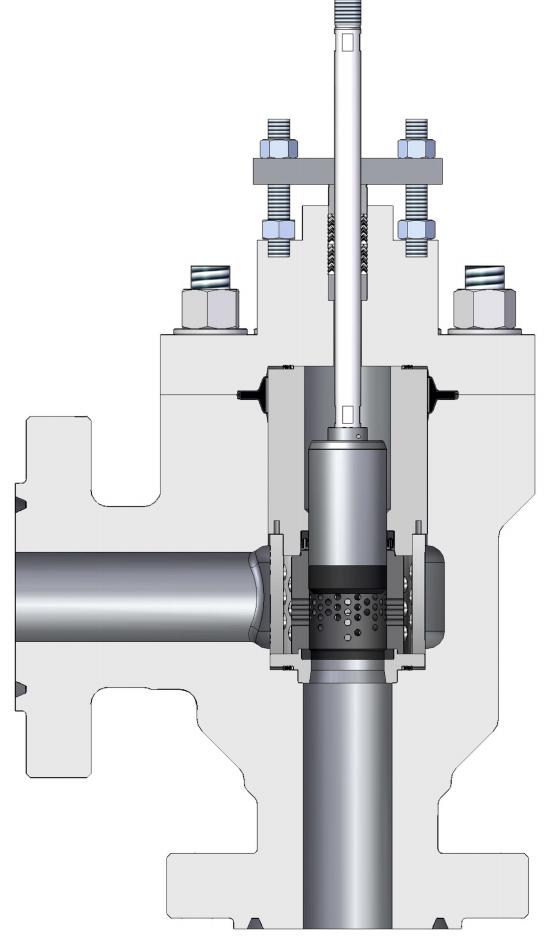

The GKV4200 High Pressure Control Choke Valve for Severe Service is designed for high-pressure control applications up to 15,000 psi, delivering robust performance and reliability in onshore and offshore oil & gas systems.

Built to API and ASME standards, it features a rigid body construction, easy top-entry maintenance, and modular trim options for effective control of erosion, cavitation, and noise under severe service conditions.

|

GKV4200 Severe Service Angle Choke Valve – High Pressure Control (5000–15000 psi)

|

|

|

Pressure Class API 5000 / 10000 / 15000 psi |

Valve Type Adjustable Choke Valve, Severe Service Control |

|

Design & Compliance Standards API 6A, API 6X, ASME Sec VIII Div. II |

Size Range 1-13/16" to 13-5/8" (API nominal sizes) |

|

Body & Bonnet Materials Carbon & Low Alloy Steel: A487 Gr. 4C, A694 Gr. F60, AISI 4130 |

Trim / Internal Materials Plug & Seat: Tungsten Carbide (Insert / Coated / Solid) |

|

Trim Styles 1CC – 4CC Concentric Cage, CCD / MLT (Multi Labyrinth Disc) |

Seal Types T-Seal (Metal-to-Metal), Wedge Seal (for MLT) |

|

Packing & Gland Options PTFE Chevron (V-ring), Graphite, or Low-Emission Packing |

Bonnet & End Connections Standard Bolted Bonnet |

|

Actuation Options Pneumatic Piston, Hydraulic, Electric, or Manual Handwheel |

Shut-off & Flow Direction ANSI FCI 70.2 Class IV (Optional Class V) |

|

Operating Temperature Range -46°C to 200°C (with PTFE Lip Seal) |

Safety Features Anti blow-out stem design |

|

Applications Oil & Gas Production Platforms |

Flow Characteristics Optimized for low pressure recovery, reduced cavitation and noise |

The GKV4200 angle choke valve series is available in angle and globe

body styles, with flanged or hub end connections conforming to API 6B/6BX

standards.Constructed from high-strength forged or cast materials, these valves

are built to API 60K / 75K material ratings, ensuring mechanical integrity and

corrosion resistance.

Pressure Class: 5000, 10000 & 15000 psi

Shut-off Class: ANSI–FCI 70.2 Class IV (optional Class V)

Flow Direction: Flow Over (standard per API 6A 14.15.2.6)

Body Materials: Carbon Steel, Duplex, Inconel, Super Duplex

Trim Options: 1CC–4CC, CCD/MLT, LRP, DPMST/LMST Microspline

Seal Types: T-Seal, Wedge Seal, Spiral Wound, PTFE Lip Seal

Packing Options: PTFE Chevron, Graphite, Low-Emission Sealing

Actuation: Pneumatic, Hydraulic, Electric, or Manual

Compliance: NACE MR0175 / ISO 15156

The interchangeable trim design allows for easy maintenance, trim upgrades,

and flexible configurations — ensuring that one valve can serve multiple

process requirements. The balanced and unbalanced trim designs further

enhance safety and operational reliability in demanding wellhead and production

conditions.

High Pressure Capability: Rated up to 15,000 psi for critical choke and control applications.

Modular Trim System: Multiple cage, disc, and spline-style trims for customizable flow control.

Superior Erosion & Cavitation Resistance: Tungsten carbide and Inconel-based trims protect against wear and flow damage.

Top Entry Maintenance: Quick access to internal components for simplified servicing and reduced downtime.

Flexible End Connections: API 6B/6BX flanged or hub-end options with integral or studded configurations.

Enhanced Sealing Integrity: Metal-to-metal T-seal, spiral wound, and wedge seals ensure leak-tight operation.

Low Fugitive Emission Packing: Graphite and PTFE lip seals comply with ISO15848 for environmental protection.

Safety-Driven Design: Anti blow-out stem, pressure relief mechanism, and balanced sealing options.

Actuation Versatility: Available in pneumatic, hydraulic, electric, or hand-operated configurations.

Proven in Field: Successfully deployed across offshore platforms, onshore oil fields, and surface wellhead systems.

|

GKV4200 Severe Service Choke Valve – High Pressure Control (5000–15000 psi)

|

|

|

Pressure Class API 5000 / 10000 / 15000 psi |

Valve Type Adjustable Choke Valve, Severe Service Control |

|

Design & Compliance Standards API 6A, API 6X, ASME Sec VIII Div. II |

Size Range 1-13/16" to 13-5/8" (API nominal sizes)

|

|

Body & Bonnet Materials Carbon & Low Alloy Steel: A487 Gr. 4C, A694 Gr. F60, AISI 4130 |

Trim / Internal Materials Plug & Seat: Tungsten Carbide (Insert / Coated / Solid) |

|

Trim Styles 1CC – 4CC Concentric Cage, CCD / MLT (Multi Labyrinth Disc) |

Seal Types T-Seal (Metal-to-Metal), Wedge Seal (for MLT) |

|

Packing & Gland Options PTFE Chevron (V-ring), Graphite, or Low-Emission Packing |

Bonnet & End Connections Standard Bolted Bonnet |

|

Actuation Options Pneumatic Piston, Hydraulic, Electric, or Manual Handwheel |

Shut-off & Flow Direction ANSI FCI 70.2 Class IV (Optional Class V) |

|

Operating Temperature Range -46°C to 200°C (with PTFE Lip Seal)

|

Safety Features Anti blow-out stem design |

|

Applications Oil & Gas Production Platforms |

Flow Characteristics Optimized for low pressure recovery, reduced cavitation and noise |