What Are You Looking For?

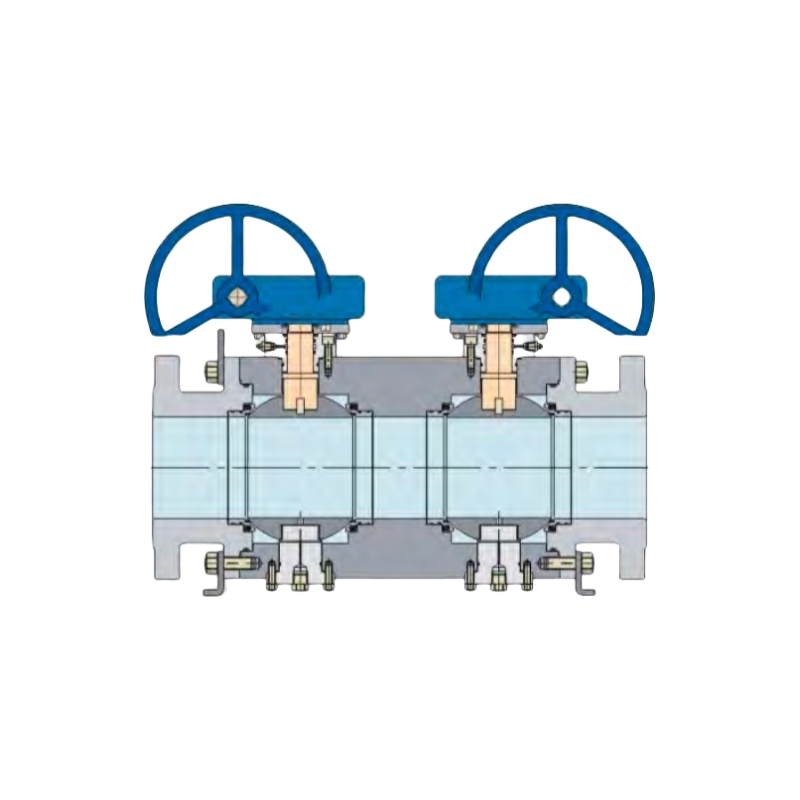

DBB The GEKO Double Block and Bleed Trunnion Mounted Ball Valve is engineered for maximum safety, reliability, and performance in critical process applications. Featuring a twin ball design within a single valve body, this valve provides true double isolation and bleed (DBB) functionality — ensuring complete separation between upstream and downstream flow lines.

It is widely used in pipelines, pumping and compression stations, offshore and onshore facilities, cryogenic systems, and high-temperature or abrasive services. The compact twin-ball configuration reduces both installation space and overall weight, delivering exceptional cost efficiency and enhanced line integrity.

|

GEKO Double Block & Bleed (DBB) Valve – Compact Isolation with Zero Leakage Assurance

|

|

|

Size Range 1/2" to 12" (DN15 to DN300), larger sizes available on request |

Body & Bonnet Material A105 / LF2 / F304 / F316 / F316L / Duplex / Super Duplex / Inconel / Monel |

|

Temperature Range -46°C to +250°C (optional extended range up to 400°C) |

Pressure Rating ASME Class 150 – 2500 (PN16 – PN420) |

|

Valve Type Double Block & Bleed – Ball / Plug / Needle type bleed design |

Seat Material PTFE / RPTFE / PEEK / Metal-to-Metal (Stellite / Inconel Overlay) |

|

Stem / Shaft Material SS316 / SS316L / 17-4PH, anti-blowout design, optional hard coating |

Bolts & Nuts B7 / B8 / L7 / B8M with 2H or 4/7 Nuts per ASTM A193/A194 |

|

Packing & Gland Graphite / PTFE / low-emission packing, live-loading design

|

End Connection Options Flanged (ASME B16.5 / EN1092), Screwed (NPT / BSPT), Socket Weld (SW), |

|

Operation Method Manual Lever / Gear / Pneumatic / Hydraulic / Electric Actuator |

Design Standards API 6D / API 598 / ASME B16.34 / BS EN ISO 17292 |

|

Testing & Inspection Pressure & Leakage Test: API 598 / ISO 5208 |

Design Features Two independent sealing barriers with bleed port, compact design, fire-safe & anti-blowout stem, low torque, full bore flow, easy maintenance

|

|

Applicable Medium Oil & Gas, Petrochemical, LNG, Chemical Process, Utility Gas, High Pressure Steam |

Installation Orientation Horizontal or vertical mounting; vent / drain port available for safe pressure release |

|

Testing & Certification EN10204 3.1 / 3.2 Material Certificates, PMI / NACE MR0175 / MR0103 compliance, ATEX & PED certified on request |

Key Highlights Zero leakage, compact structure, fire-safe design, double sealing integrity, easy maintenance, suitable for isolation and venting in high-pressure systems |

Each valve integrates two independently operated trunnion-mounted ball

valves within one body, separated by a central cavity equipped with a drain

valve. This configuration enables operators to safely vent, test, or drain the

intermediate chamber, confirming tight shut-off on both sides.

Both valves retain all the premium features of GEKO’s side-entry trunnion

ball valves, including:

* Floating independent seat rings for reliable sealing under variable pressures.

* Single Piston Effect (SPE) or Double Piston Effect (DPE) seat design,

depending on customer requirements.

* Availability in soft- or metal-seated configurations, suitable for a wide

range of fluids and operating conditions.

* Optional internal overlay and extended stem for buried or insulated pipeline

applications.

* Compatible with all standard actuation methods (manual, pneumatic, electric,

or hydraulic).The result is a robust and compact DBB solution offering higher

safety, reduced maintenance, and minimal pressure loss.

Advantages:

- Compact twin-valve design reduces face-to-face length and total weight.

- Ensures complete isolation and safe pressure venting between two barriers.

- Lower installation and maintenance costs with enhanced operational safety.

- Flexible configuration suitable for both low and high-pressure systems.

Key Features:

* Design Type: 1/3 Piece Body, Full or Reduced Bore

* Operation: Trunnion Mounted, Double Block and Bleed (DBB)

* Seat Design: SPE/DPE configuration, Spring-Loaded Seats

* Safety & Reliability:

- Anti-Blowout Stem & Anti-Static Device

- Fire Safe Design per API 607 / API 6FA / ISO 10497

- NACE MR0175 Compliance for sour service

- Sealant Injection System for emergency sealing

* Performance Range:

- Size: 1" ~ 24"

- Pressure Class: ASME 150 – 2500 / API 2000 – 15000

- Design Standards: API 6D, API 6A, ASME B16.34

* Material Options:

- Stem Material:

* ≥205 MPa yield for 150/300 LB

* ≥360 MPa yield for 600/900 LB

* ≥450 MPa yield for 1500/2500 LB

- Seat Material:

* PTFE, RPTFE, DEVLON, or PEEK (varies by size and pressure class)