What Are You Looking For?

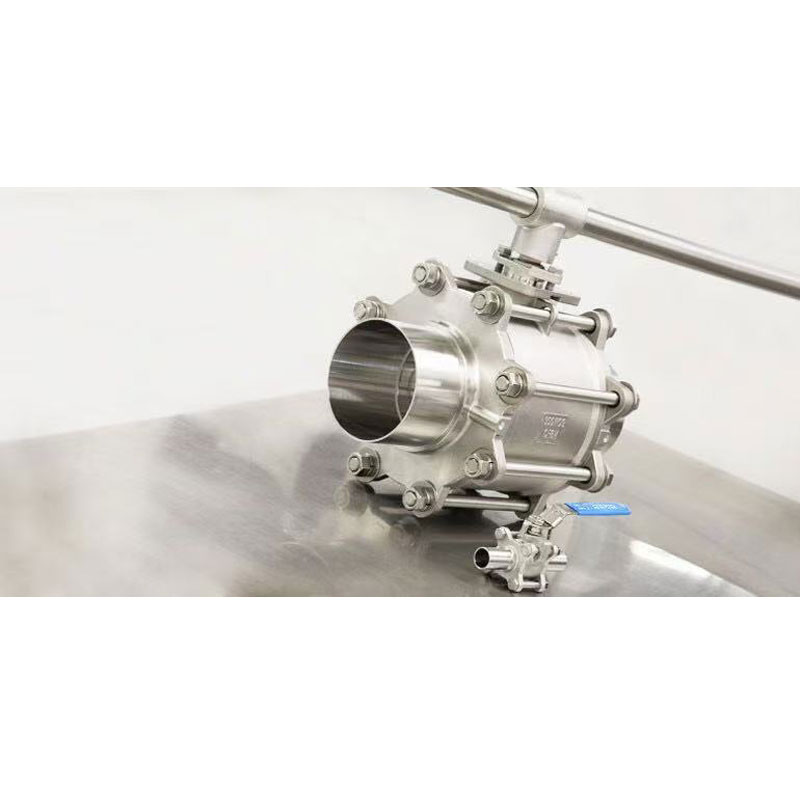

GEKO GKV-32T/B Ultra Clean Ball Valve is a high-purity hygienic valve designed specifically for industries with strict sanitary requirements — including food processing, beverage production, pharmaceuticals, and cosmetics.

Engineered with a three-piece swing-out design, it allows for easy disassembly, thorough cleaning, and reliable maintenance, minimizing contamination risks and ensuring smooth, sterile flow throughout your process system.

Built with SUS304 or SUS316L stainless steel, the valve delivers outstanding corrosion resistance, durability, and compliance with GMP, FDA, ISO, DIN, and 3A standards. Its mirror-polished interior (Ra ≤ 0.2 μm) ensures ultra-clean flow with no dead angles, making it ideal for CIP/SIP cleaning operations.

|

GEKO GKV-32T/B Three-Piece Ultra Clean Ball Valve – High Purity, Hygienic, Easy Maintenance

|

|

|

Size Range 1/2" – 4" (DN15 – DN100), custom sizes available

|

Body & Bonnet Material SS304 / SS316L stainless steel, fully polished wetted parts, FDA/GMP/3A compliant |

|

Temperature Range Up to 180°C (356°F) |

Stem / Shaft Material SS304 / SS316L stainless steel, blow-out proof, reinforced packing ring |

|

Maximum Allowable Working Pressure 1000 PSI (PN64) |

Seats & Seals PTFE, high-purity, chemically resistant, self-lubricating |

|

Packing & Gland PTFE reinforced packing, oil-free, high-purity, suitable for CIP/SIP |

Bolts & Nuts SS304 / SS316L stainless steel matching valve material |

|

Special / Optional Materials SS316L for corrosive media, custom alloys on request |

Operation Method Manual (90° rotation), optional Pneumatic or Electric actuation via ISO5211 pad |

|

Special Design Features Swing-out three-piece body, full-bore flow, no dead zones, CIP/SIP ready, easy field maintenance |

End Connection Standards Tube Weld, Butt Weld, T-Clamp, Threaded, Flanged (ASME BPE / ISO / DIN)

|

|

Design Standards GMP, FDA, ISO, DIN, 3A Sanitary Standards |

Applications Food, Beverage, Pharmaceutical, Cosmetics, Dairy, Biotech, Chemical Industry |

|

Testing & Inspection Seat Test (Air): 80 PSI; Shell Test (Hydrostatic): 1500 PSI; CIP/SIP Function Test; Leak Test |

Key Highlights Ultra-clean, hygienic, easy maintenance, full-port flow, low pressure drop, durable, corrosion resistant, automation ready |

Model: GKV-32T/B

Design: 3-piece high-purity clean ball valve (Tube / T-Clamp / Butt Weld End)

Material: SS304 / SS316L stainless steel

Size Range: 1/2" – 4" (DN15–DN100)

Working Pressure: 1000 PSI (PN64)

Temperature Range: Up to 180°C

Testing Pressure: - Seat (Air): 80 PSI. - Shell (Hydrostatic): 1500 PSI

Mounting Pad: Built-in ISO 5211 pad for easy actuator installation

Polishing: Ra 0.1 μm mirror finish

Sealing Material: Imported PTFE, ensuring high chemical resistance

and tight sealing performance.

Cleaning: Oil-free, high-purity cleaning process

Connections: Tube weld ends / T-clamp / Threaded / Flanged options

Standards: FDA / GMP / 3A / ISO / DIN compliant

| Inspection Criteria | |||||

| Grade Of Finish of Pipes | ID Surface Roughness,Ra | Oil Residual | Particle Level | ||

| AP Finish | 一 | <0.1mg/ft² | 一 | ||

| MP(BA)Finish | OD≤40A:Ra≤0.38μm | <0.1mg/t² | >0.1μm, Max.5PC |

||

| OD 50A-150A:Ra≤0.5μm | |||||

| OD 200A-800A:Ra≤0.6μm | |||||

| EP Finish | OD≤20A:Ra≤0.15μm | <0.01mg/ft² | >0.1μm, Max.1PC |

||

| OD 25A-50A:Ra≤0.2μm | |||||

| OD 65A-100A:Ra≤0.25μm | |||||

| Manufacturing Process Of AP,MP(BA)and EP | ||||

| Grade Of Finish of Pipes | AP Finish | MP(BA)Finish | EP Finish | |

| ID bead-cut,bead removed | NO | YES | 一 |

|

| ID mechanical polishing | NO | YES | 一 | |

| RO Water Cleaning | YES | YES | 一 | |

| DI Water Rinsing | NO | YES | YES | |

| Chemical Passivation | Acid Pickled | YES | YES | |

| Clean Room,Class 1000 Cleaning and Bagging |

Option | YES | YES | |

| Double Sleeve Bagging | Option | YES | YES | |

Key Features & Advantages:

? Ultra-Clean & Hygienic Design

Full-bore passage with a polished internal surface ensures smooth, uninterrupted

flow and prevents media residue or bacterial growth.

Perfect for aseptic and sterile applications.

? Easy Maintenance — Swing-Out Three-Piece Body

Allows quick field disassembly without removing the entire valve from the pipeline.

Simplifies cleaning and reduces system downtime.

? Full Port, True Bore Flow Path

Provides minimal pressure drop and unrestricted media passage — ideal for viscous or particle-laden fluids.

? CIP/SIP Ready

Integrated bosses for Steam-In-Place (SIP) and Clean-In-Place (CIP) connections

make it suitable for fully automated sanitization systems.

? Built for Automation

Equipped with ISO 5211 mounting pad, allowing easy integration with pneumatic

or electric actuators for remote control.

? Premium Sealing Performance

PTFE seals and reinforced packing deliver exceptional tightness and chemical

compatibility under both vacuum and high-pressure conditions.

? Superior Material & Construction

All wetted parts in SS316L for orbital welding compatibility; oil-free assembly

ensures compliance with high-purity requirements.