What Are You Looking For?

Recently, Shuangliang Energy System Co., Ltd. announced the signing of a strategic cooperation framework agreement with IDEA-TSG, a leading multinational engineering group headquartered in Spain. The agreement was officially signed in Madrid, marking an important milestone in the global deployment of scalable, low-cost decarbonization solutions, particularly in the green hydrogen and renewable energy sectors.

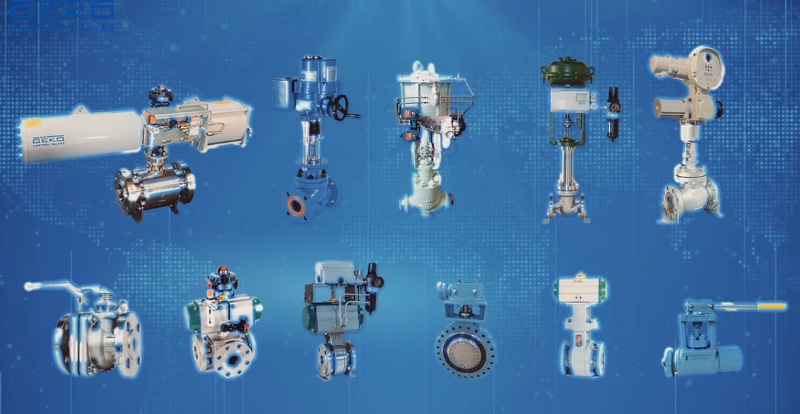

As a professional industrial valve manufacturer, GEKO Valves closely follows and actively supports such international collaborations, which are reshaping the future of EPC projects, hydrogen production systems, and sustainable energy infrastructure worldwide.

IDEA-TSG is an experienced engineering and EPC group with operations in 26 countries, providing turnkey solutions across power distribution systems, renewable energy integration, and industrial EPC projects. The group has extensive project experience in oil & gas, mining, and heavy industrial applications, where reliable flow control and valve safety performance are mission-critical.

In large-scale EPC projects, industrial valves are key components that ensure:

Safe isolation and precise flow regulation

High-pressure and high-temperature process control

Long-term operational reliability and compliance with international standards

Shuangliang Energy is a leading technology and equipment provider in energy-saving systems and green hydrogen solutions. Its newly developed 5000 Nm³/h alkaline water electrolysis hydrogen production system is currently one of the world’s largest-capacity alkaline electrolyzers, featuring high current density and low energy consumption.

In alkaline water electrolysis and hydrogen production systems, hydrogen valves and process control valves play a vital role in:

Safe separation and isolation of hydrogen, oxygen, and electrolyte media

Leak-tight performance under high-pressure hydrogen service

Emergency shut-off, start-up, and system interlocking

GEKO Valves supplies industrial valves for hydrogen, ammonia, and renewable energy applications, engineered to meet the stringent requirements of green hydrogen EPC projects.

The cooperation between Shuangliang Energy and IDEA-TSG will focus strongly on Front-End Engineering Design (FEED) and Basic Engineering Design Packages (BEDP). At these early project stages, valve selection and flow control design have a direct impact on:

Process safety (HAZOP studies)

System efficiency and energy consumption

CAPEX and lifecycle operating costs

Compliance with API, ASME, ISO, ATEX, and other global standards

GEKO Valves actively supports EPC contractors, package unit suppliers, and system integrators by participating in early-stage engineering discussions, providing optimized valve solutions tailored to hydrogen and renewable energy processes.

To address common industry challenges such as high project costs, scalability limitations, and regulatory complexity, modular system design is becoming increasingly important. GEKO Valves offers:

Modular valve packages for skid-mounted and packaged systems

Custom-engineered valve solutions for hydrogen, ammonia, and industrial gases

Reliable delivery for international EPC projects and overseas installations

With proven manufacturing capability and strict quality control, GEKO Valves supports customers throughout the entire project lifecycle, from design and manufacturing to commissioning and long-term operation.

The partnership between Shuangliang Energy and IDEA-TSG reflects a broader global trend toward clean energy supply chains and low-carbon industrial systems. As a trusted industrial valve manufacturer, GEKO Valves remains committed to supporting green hydrogen, renewable energy, and EPC projects with high-quality valve and flow control solutions.

By continuously investing in engineering expertise, product reliability, and international project support, GEKO Valves contributes to safer, more efficient, and more sustainable energy infrastructure worldwide.