What Are You Looking For?

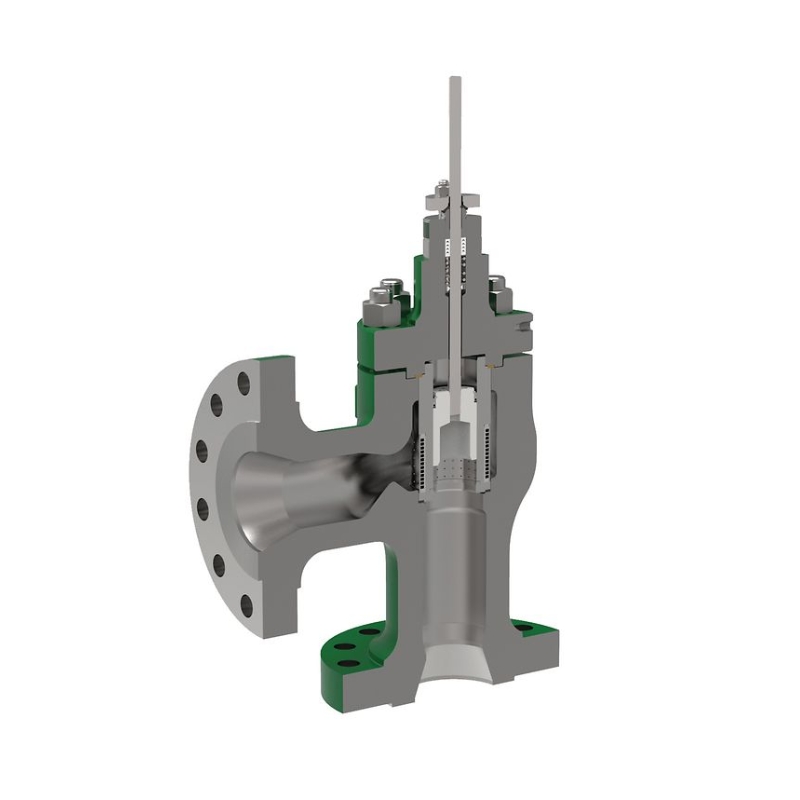

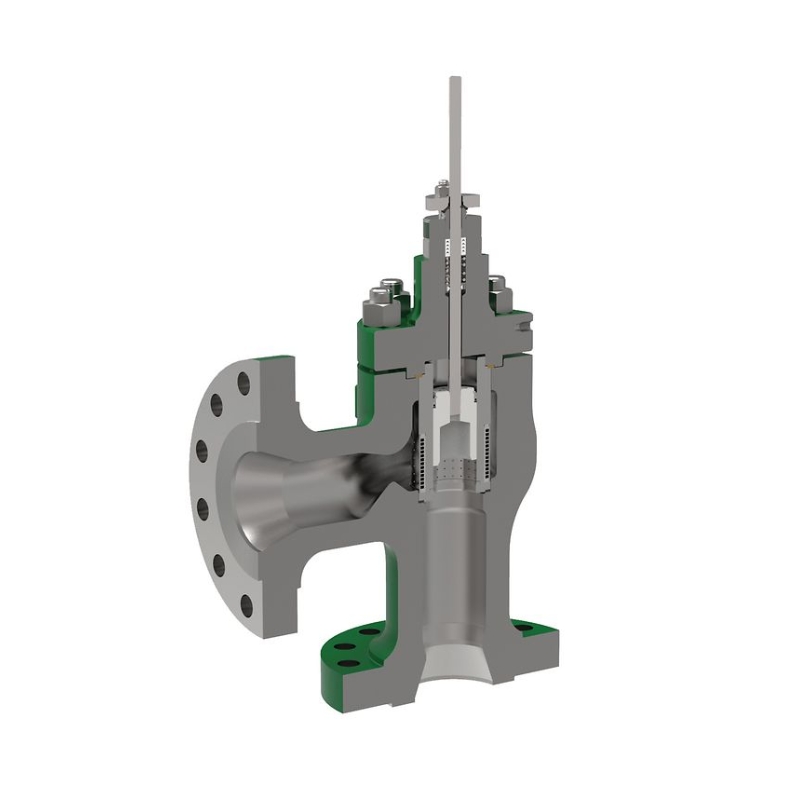

The GEKO Angular Control Valves of the series GKV3500 (PN 16 - 250) and GKV3800 (PN 16 - 400) are part of the well proven GEKO valve modular parts system. In case of difficult working conditions and sonic relevant applications it is often recommended to use angular valves, because the flow of the medium is turned only once by 90°, contrary to single or double seated valves.

|

GKV3500/3800 SANGLE CONTROL VALVE

|

|

|

Size Range DN25 to DN600/ 1” to 24” |

Body Materials Stainless Steel , Carbon Steel,Titanium, Zirconium , Tantalum, Hastelloy, nickel-based alloys, Monel alloys, Alloy20,F51, F22, 904L |

|

Temperature Range -196℃ to 530℃ |

Stem Materials ASTM A479 Type 316, ASTM A564 Type 17-4PH, ASTM A182 Type F51 |

|

Maximum Allowable Operating Pressure ASME Class 150LB to 2500LB, EN 1092 PN10 to PN420 |

Seat Materials Soft seal, stainless steel, alloy |

|

Shutoff Rating Manufacturer's standard |

Plug Materials Stainless steel, alloy |

|

Body Style Angle |

Design Standard ANSI, DIN, GB,JIS, ISO, EN |

|

End Connections Socket Weld, Butt Weld, Flanged End |

Testing standard API 598 |

|

Ports Narrowing the flow channel |

Connect Platform Manufacturer's standard |

|

Face To Face Manufacturer's standard |

Applications Pressure Control, Temperature Control, Flow Control, Steam Control, Cavitation |

Features of GKV3500/3800 Series Angle Control Valve

For challenging process conditions and sonic-critical applications, GEKO angular control valves offer an optimal solution. Unlike conventional single- or double-seated valves, the medium flow in angular valves is redirected only once at a 90° angle, which significantly reduces turbulence, erosion, and pressure losses. This design ensures stable performance even under severe service conditions such as cavitation, flashing, or high differential pressures.

Reliable Actuation

As standard, the valve is equipped with GEKO’s proven diaphragm

operated actuator, designed to be enclosed, reversible, and

maintenance-friendly.

This ensures smooth control response and long service life, even with

high cycling frequencies.

Flexible Actuator Options

To meet diverse automation needs, the valve can also be fitted with

pneumatic, hydraulic, electric, or manual drive actuators, enabling

seamless integration into any control system architecture.

Modular Trim System

Leveraging the GEKO® modular parts system, the internal trims are fully

adaptable and interchangeable. Options include hardened trims for erosive

media, low-noise cage-guided trims, multi-stage pressure-reducing trims,

or special materials for corrosive environments. This modularity allows

the valve to be precisely tailored to process requirements, ensuring

maximum reliability and efficiency.

By combining a robust angular design, flexible actuation methods, and modular internal components, GEKO angular control valves provide superior performance, extended service life, and versatile application possibilities in industries such as oil & gas, chemical, petrochemical, and power generation.

Advantages of GKV3500/3800 Series Angle Valve

Proven Diaphragm Actuator

Equipped as standard with the enclosed, reversible GEKO diaphragm actuator

for stable, accurate control.

Multiple Drive Options

Available with pneumatic, hydraulic, electric, or manual actuation.

Modular Design

Interchangeable trims and internal parts from the GEKO® modular system for

easy customization.

Versatile Configurations

Various spindle bushings—with cooling fins, insulating columns, or bellows

sealing—can be exchanged as needed.

Material Flexibility

Adaptable to different media and pressure classes through a wide selection

of materials.

GEKO angle regulating valve is applied in multiple industries

Petrochemical and natural gas industries

Petrochemical and natural gas industries

Municipal water supply and HVAC engineering

Municipal water supply and HVAC engineering

Ship and Ocean Engineering

Ship and Ocean Engineering

Environmental Protection and Industrial Water Treatment

Environmental Protection and Industrial Water Treatment