What Are You Looking For?

GKV200/220 three-way regulating valve For extremely short on/off cycles in the cooling spray lines of wire rolling mills we developed these three-way on/off control valves. Already for several years they are performing excellently under these severe conditions and guarantee a long life cycle.

|

GKV200/220 SERIES THREE WAY VALVE

|

|

|

Size Range DN25 to DN500/ 1” to 20” |

Body Materials Stainless Steel , Carbon Steel,Titanium, Zirconium , Tantalum, Hastelloy, nickel-based alloys, Monel alloys, Alloy20,F51, F22, 904L |

|

Temperature Range -196℃ to 530℃ |

Stem Materials ASTM A479 Type 316, ASTM A564 Type 17-4PH, ASTM A182 Type F51 |

|

Maximum Allowable Operating Pressure ASME Class 150LB to 2500LB, EN 1092 PN10 to PN420 |

Seat Materials Soft seal, stainless steel, alloy |

|

Shutoff Rating Manufacturer's standard |

Plug Materials Stainless steel, alloy |

|

Body Style Three direct links |

Design Standard ANSI, DIN, GB,JIS, ISO, EN |

|

End Connections Socket Weld, Butt Weld, Flanged End |

Testing standard API 598 |

|

Ports Narrowing the flow channel |

Connect Platform Manufacturer's standard |

|

Face To Face Manufacturer's standard |

Applications Pressure Control, Temperature Control, Flow Control, Steam Control, Cavitation |

GKV200/220 Series Three Way Valve

GEKO three-way control valves are widely applied across various thermodynamic and industrial processes due to their reliability and precise flow control.

Flexible Actuation Options

The valves can be equipped with pneumatic or electric actuators, providing smooth and precise control while enabling integration into automated process systems.

Optimized Hydrodynamics

GEKO three-way valves are designed with advanced internal flow paths to achieve optimal mixing or flow dividing, minimizing turbulence, pressure loss, and energy consumption.

Process Adaptability

The modular design and versatile trim options allow precise adaptation to your specific process requirements, ensuring maximum efficiency, stability, and reliability under various operating conditions.

Typical applications include:

- Marine cooling systems for motor ships

- Heating and cooling systems for chipped

wood processing and plate pressing

- Vulcanising and other press operations

- High-pressure applications such as

transfer, compression, and pre-heating stations

- Overheating processes in power generation plants

With a combination of robust construction, optimal flow dynamics, and flexible actuation, GEKO three-way valves deliver high performance and long-term reliability in demanding industrial environments.

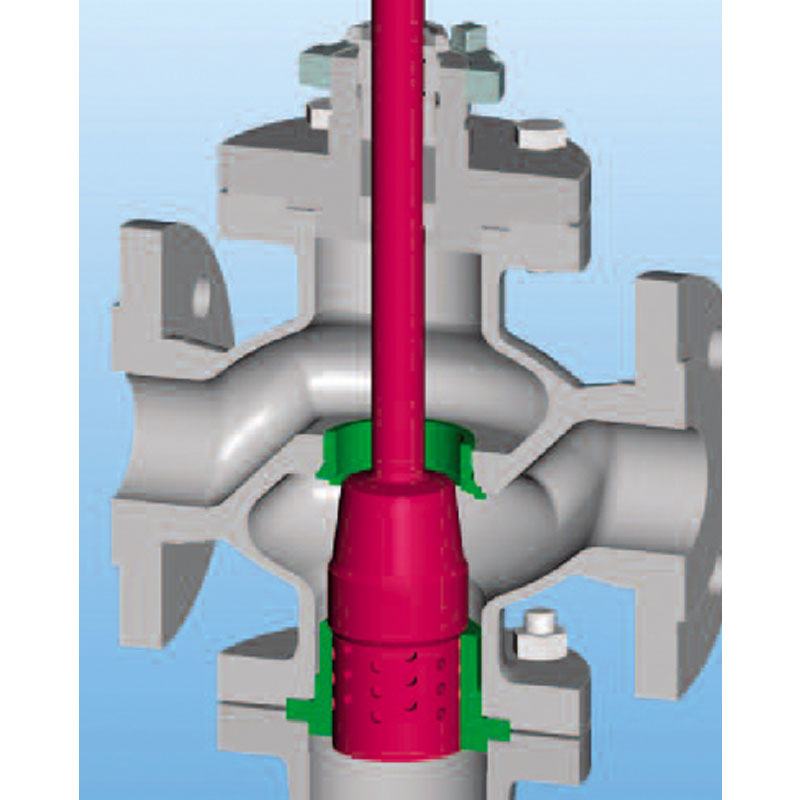

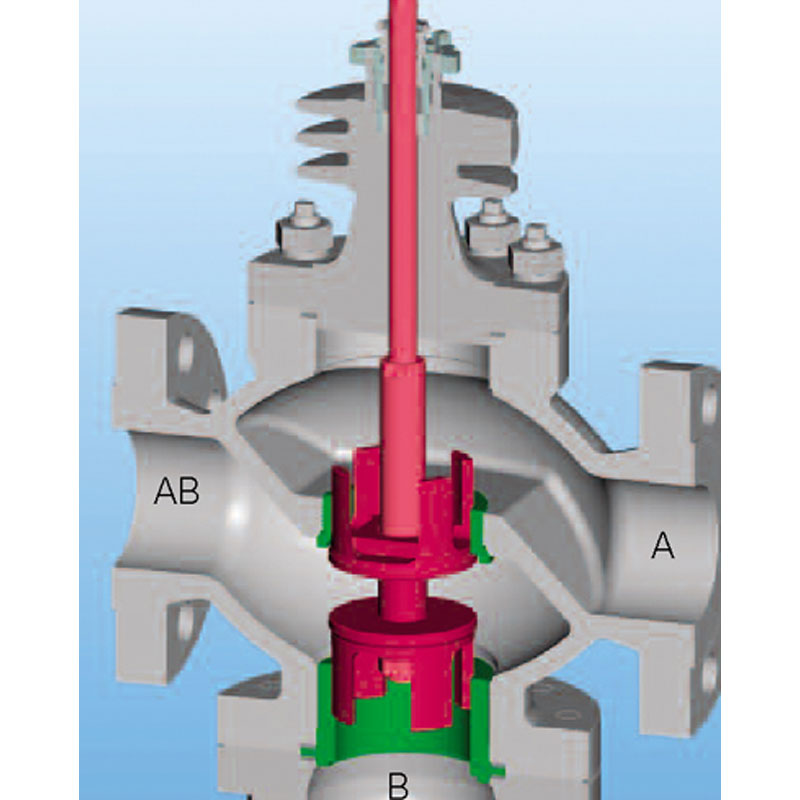

Unique Design of GKV200/220 Series Three Way Control Valve

Flexible Flow Configurations

The valve body is designed to support split-type operation (one inlet, two outlets) and merge-type operation (two inlets, one outlet). This flexibility allows the valve to efficiently perform fluid mixing, heating, or cooling, as well as uneven fluid splitting, depending on the specific process requirements.

High-Precision Actuation

The multi-spring actuator provides smooth, stable, and reliable movement of the dual valve cores, ensuring accurate flow regulation and minimal wear over extended operation.

Adaptable to Various Working Conditions

With this advanced design, the valve can handle a wide range of pressures, temperatures, and media, making it suitable for industrial heating/cooling circuits, chemical processes, and complex fluid distribution systems.

By combining dual-core guidance, multi-spring actuation, and versatile four-way body design, the GEKO Three-way control valve achieves high efficiency, precise control, and reliable operation in demanding industrial applications.

GEKO three-way regulating valves are used in multiple industries

Petrochemical and natural gas industries

Petrochemical and natural gas industries

Municipal water supply and HVAC engineering

Municipal water supply and HVAC engineering

Ship and Ocean Engineering

Ship and Ocean Engineering

Environmental Protection and Industrial Water Treatment

Environmental Protection and Industrial Water Treatment