Top 8 Global Industrial Valve Manufacturers

Nov 30, -0001

According to a joint market research report, the global industrial valve market is expected to grow from $585.479 billion in 2020 to $936.649 billion in 2028, with a compound annual growth rate of 6.0%. Today, let's take a look at the top 8 industrial valve manufacturers worldwide in 2023.

01.Emerson(America)

Emerson is a globally leading provider of industrial automation and technology solutions, founded in 1890 in the United States, boasting a history of 133 years to date. Committed to delivering innovative industrial solutions across various industries, it stands as a leading enterprise in the fields of industrial control, automation, process management, and fluid control. Emerson owns numerous brands, with the FISHER brand in the valve business being particularly well-known, distinguished by its characteristic green coating.

02.FLOWSERVE (America)

Flowserve is a long-standing and continuously evolving company with a history dating back to 1790 in London, United Kingdom. With a legacy spanning over 200 years, it surpasses Emerson's history by a century. Today, Flowserve has become a publicly traded company with an annual revenue exceeding $4 billion, boasting a workforce of over 17,500 employees. Its operations extend to more than 50 countries/regions, with over 300 branches worldwide.

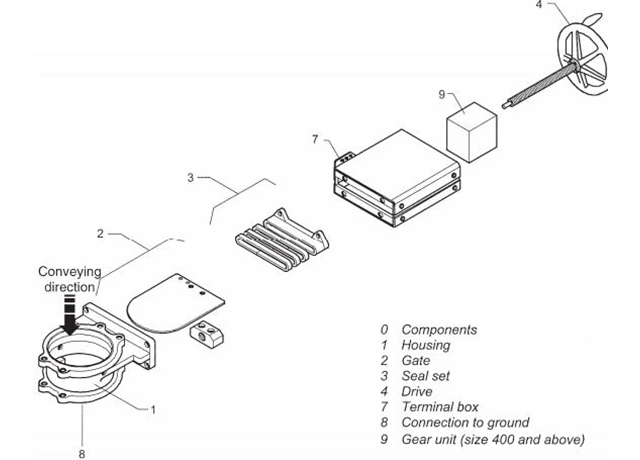

Their business scope includes pumps, sealing components, valves, drives and instruments, energy recovery devices, hydraulic decoking systems, and more. Unlike FISHER, FLOWSERVE prefers to use red and white paint on their actuators and valves. Below are reference images of FOS valve products.

03. KSB(Germany)

04.KITZ (Japan)

KITZ is one of the largest valve manufacturers in Japan, founded in 1951 as the first manufacturer in Japan to use a brass hot forging press. The KITZ Group comprises three main business segments: the core valve manufacturing business, brass bar manufacturing business, and other businesses. The valve manufacturing business constitutes over 80% of the total sales. KITZ valves find extensive applications in various industries such as petroleum, chemicals, pharmaceuticals, energy, and more, with consistently growing sales in the domestic market. The valve production process at KITZ involves...(文字外链:https://mp.weixin.qq.com/s/K9TIR43NQLD_zLFLVimjxg)

05.VELAN(Canada)

Velan is an international valve manufacturer headquartered in Canada, founded in 1950. It is one of the world's leading industrial valve manufacturers, specializing in forged ball valves, forged gate valves, forged globe valves, forged check valves, and steam traps. Velan's valves primarily operate in critical industries, namely under high-pressure, high-temperature, or low-temperature conditions, holding significant positions in sectors such as petroleum, natural gas, nuclear energy, and others.

The acquisition agreement between Flowserve and Velan has been terminated.

06.Bray(America)

Bray is an American manufacturer of industrial valves and control systems, founded in 1986. It is one of the world's leading manufacturers of flow control and automation products and accessories. Its primary products include actuators, ball valves, butterfly valves, check valves, knife gate valves, and other accessories. The majority of its products are used in industries such as alternative fuels, petrochemicals, food and beverage, general industry, marine, mining and metallurgy, oil and gas, pharmaceuticals and biotechnology, power generation, pulp and paper, as well as water and wastewater treatment.

07.IMI(UK)

The history of IMI can be traced back to 1862, and it is a multinational industrial manufacturer based in the United Kingdom. The valve business is managed by IMI Critical Engineering, a company specializing in the production of highly specialized valves and actuators designed for extreme temperatures and pressures, as well as harshly abrasive or corrosive industrial conditions.

08.AVK(Denmark)

AVK was founded in 1941, initially focusing on the production of compressors for refrigeration and freezing equipment. The AVK Group is dedicated to three main business segments: AVK Water, AVK Industrial, and AVK Advanced Manufacturing. AVK Water primarily serves the water supply, gas supply, sewage treatment, and firefighting industries, offering a wide range of valves, hydrants, and accessory products. AVK Industrial, with companies like Orbinox, InterApp, and Wouter Witzel, provides comprehensive valve solutions to customers in water treatment, power generation, oil and gas, marine, pulp and paper, mining, and chemical industries.

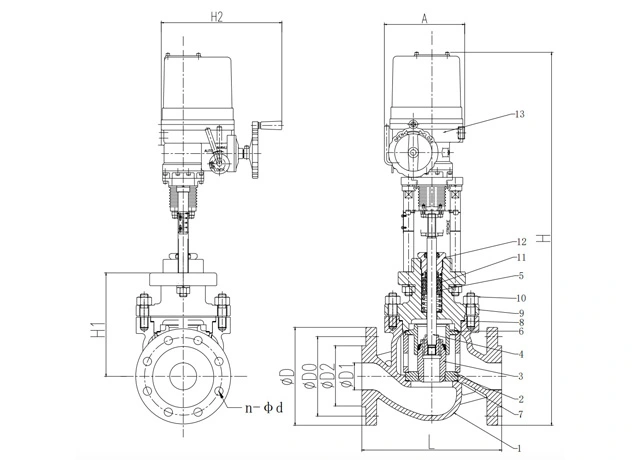

GEKO control valves are renowned for their precision, reliability, and innovative design in fluid control systems. Crafted with cutting-edge technology and superior engineering, GEKO valves excel in providing accurate and efficient regulation of various fluids in industrial processes. Whether it's optimizing flow rates, maintaining pressure, or ensuring precise temperature control, GEKO control valves stand out for their exceptional performance. With a commitment to quality and a focus on meeting the most demanding industry requirements, GEKO continues to be a trusted choice for critical applications where precise fluid control is paramount. Elevate your fluid handling systems with GEKO control valves and experience the epitome of excellence in control valve technology.

Read More