Hydrogen Valves — Configuration, Applications, Functions, and Prospects

Jun 04, 2024

"In recent years, with clean energy becoming a hot topic, the hydrogen industry has received increasing attention. On one hand, there is a growing demand for hydrogen in the market; on the other hand, industrial valves involved in hydrogen applications may have certain safety hazards. In this rapidly evolving industry, ensuring safety must consider various aspects, such as material selection, design verification testing, and fugitive emission testing.

Hydrogen is the smallest known molecule in nature and as an energy source, it has unlimited application potential. Hydrogen gas is extremely flammable, and hydrogen valves play a crucial role in controlling hydrogen flow, ensuring the safety of personnel, equipment, and the environment. Info@geko-union.com

01

Valve Selection -

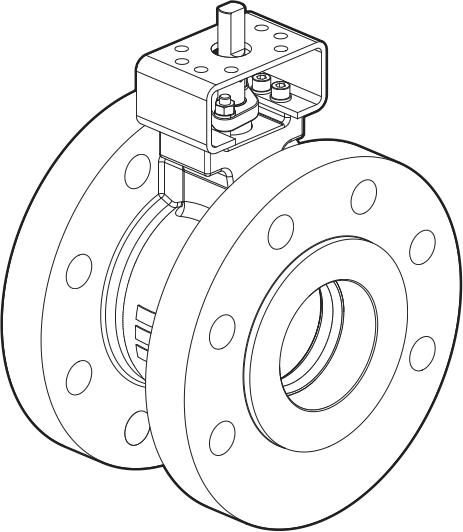

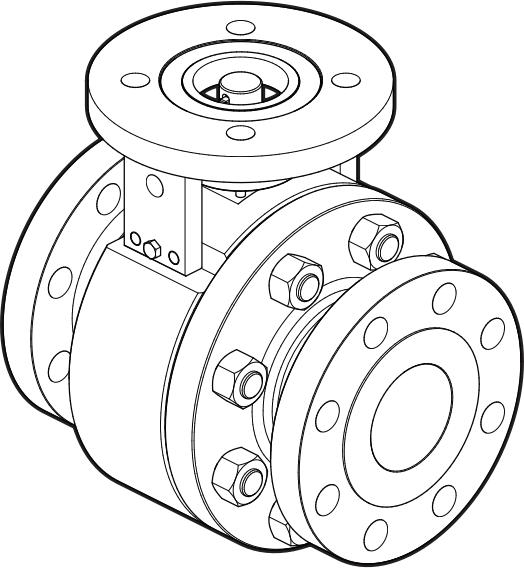

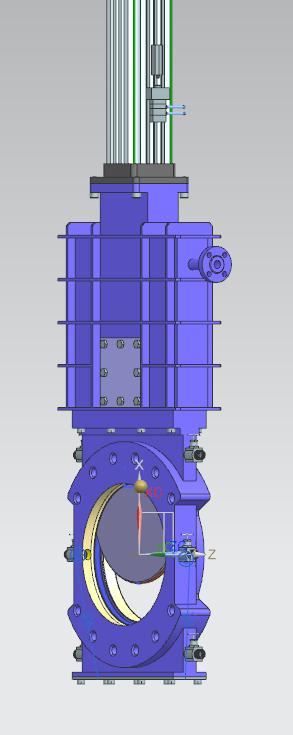

For valves used in hydrogen conditions, correct selection is absolutely essential for equipment safety and reliable operation. Common types of hydrogen valves include ball valves, globe valves, and check valves. Ball valves are an ideal choice for on-off functions, with excellent shut-off capabilities for effectively isolating hydrogen. Globe valves offer precise control and regulation functions, commonly used at nodes in hydrogen systems requiring modulation. Check valves prevent backflow, protecting system safety, and play an important role in maintaining the overall integrity of hydrogen systems. When selecting hydrogen valves, it is necessary to follow standards such as API 600, API 602, or ASME B16.34 to ensure that the valves are properly matched with the system and operate normally.

02

Basic Materials -

Choosing the right raw materials is essential for manufacturing hydrogen valves to ensure equipment safety and reliability. Common materials include stainless steel (ASTM A351 CF8M), nickel-based alloys (ASTM B564, N10276), and titanium (ASTM B348). These materials all have characteristics of hydrogen embrittlement resistance and are well suited for challenging hydrogen conditions.

Several standard associations including ASTM International, the American Petroleum Institute (API), and the American Society of Mechanical Engineers (ASME) provide guidelines on material selection and compatibility for hydrogen conditions, which are highly valuable references.

03

Design Verification Testing -

Safety is paramount, especially for hydrogen valves that must withstand the extreme challenges posed by this active gas. This means withstanding high pressures, preventing leaks, and effectively controlling fluids to minimize potential risks and protect life and property.

Valves for hydrogen conditions need to undergo design verification testing before use to confirm that they can perform their intended functions and operate reliably under demanding conditions. Recommended specific test types include engineering design calculations and simulations, as well as pressure tests. These tests can serve as simulated functional tests, evaluating the overall integrity and sealing performance of valves under high pressure and repeated cycling. It is recommended to use automated cycling operations to reduce personnel safety risks.

For hydrogen valves, the current trend is to use gas pressure tests in proportion to static water pressure tests. The main reason is that water molecules may not reveal some subtle defects in low-pressure tests. Moreover, for some valve designs, water should not be used as the test medium. Inert gases significantly improve test sensitivity. Additionally, it is necessary to conduct tests using clean, dry air, nitrogen, helium, argon, or even hydrogen to simulate actual operating conditions. Test operators must be very familiar with the associated risks and preventive measures.

High-pressure gas tests should consider using protective enclosures. Cryogenic tests are essential for verifying valve low-temperature performance, especially for hydrogen valves. Valve design and verification testing must comply with standards such as API 598 and ASME B16.34. In practical operations, it is often necessary to extend the prescribed test time or use higher-than-standard test criteria to obtain more robust assurance.

04

Fugitive Emissions -

For hydrogen valves, the primary concern in testing is not only functional tests, gas pressure tests, and cryogenic tests. To ensure that valves remain functional even under worst-case scenarios, fugitive emission testing and fire tests are also necessary.

For cost-saving considerations, can functional tests and fugitive emission tests be combined? If valves can perform their functions under the most extreme conditions, it can reduce leaks, pollution, and even prevent accidents. When conducting fugitive emission testing for industrial valves in hydrogen conditions, specialized test procedures must be followed to ensure the safety of personnel and the environment. Helium leak testing using mass spectrometry or other gas detection techniques is a commonly used, highly sensitive method for valve leak testing.

Typically, ASME V detection is used for fugitive emission testing. This method is advantageous in detecting extremely weak leaks that are not detectable by general-purpose signal measurement instruments, thereby confirming whether valves meet strict leakage standards and reducing the risk of fugitive emissions. Moreover, fugitive emission testing must comply with standards such as ISO15848-1 and API 622/624 to ensure that hydrogen valves meet environmental protection and safety requirements.

Conclusion -

In the hydrogen industry, doubling attention to all related aspects is necessary to ensure safety, including material selection, design verification testing, fugitive emission testing, valve selection, and assessing potential safety threats based on specific application scenarios. As manufacturers, shareholders, and owners, it is essential to prioritize and manage all aspects accordingly, following relevant industry standards and best practices to achieve the highest safety standards, making hydrogen a reliable, sustainable, and safe energy source. Despite the continuous expansion of the hydrogen industry, the commitment to safety remains the cornerstone of its development prospects, as only safety can win public confidence in this active energy source."

GEKO is a global leading manufacturer of valves and accessories, catering to various markets including natural gas infrastructure, downstream oil and gas industries, industrial and energy transition, pipeline systems, and power transmission infrastructure. The company offers complete valve and automation solutions. GEKO's product range is extensive, covering various manufacturers, materials, sizes, grades, and pressure ratings, capable of handling even the most extreme application conditions. Their drive products include various pneumatic, electric, and manual actuators, limit switches, positioners, as well as various installation hardware and accessories.

Many of our clients trust us and entrust us with the task of upgrading valves and automation components, ensuring that these products always meet the latest technical specifications and industry standards. With our assistance, many clients have been able to select suitable valves without much hassle, improving equipment reliability while reducing costs.

Read More