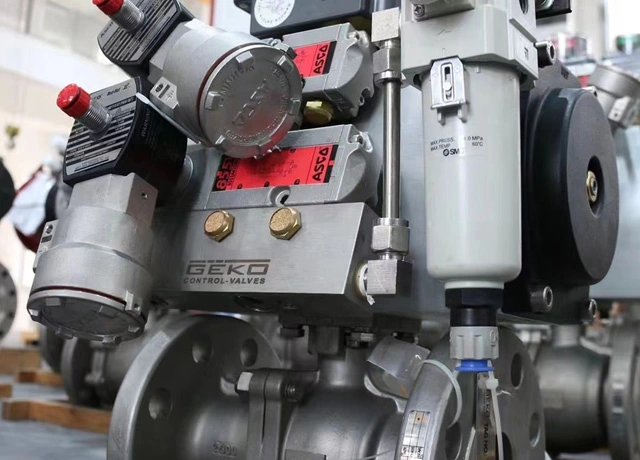

GEKO - Double solenoid valve configuration zero leakage cut off ball valve with both SIS and DCS system applicated in high-risk chemical environments

Jun 04, 2024

The Shandong GUOTAI Dacheng Technology Co., Ltd Carbon Fiber Project collaborated with GEKO valves and controls , led by Israeli experts, and formed a research and development team consisting of renowned experts from both domestic and international spheres. The project comprehensively introduced international advanced production equipment and production process technology to establish a high-end industrial chain centered around carbon fiber and composite materials, driving the formation of a multi-billion-level industry cluster. The total investment for the project is approximately 7 billion yuan, with an initial phase comprising a production line capable of annually producing 7,500 tons of precursor fibers and 3,000 tons of carbon fiber.

The project primarily focuses on the production of mid-to-high-end carbon fiber precursor fibers, carbon yarns, carbon fiber composite materials, and their processed products. Some of these products are expected to break international monopolies and address domestic gaps. The applications of these products are widespread and include military industries, aerospace, new energy sectors, rail transportation vehicles, wind power generation, fuel cells, pressure vessels, sports, and leisure, among various other fields.

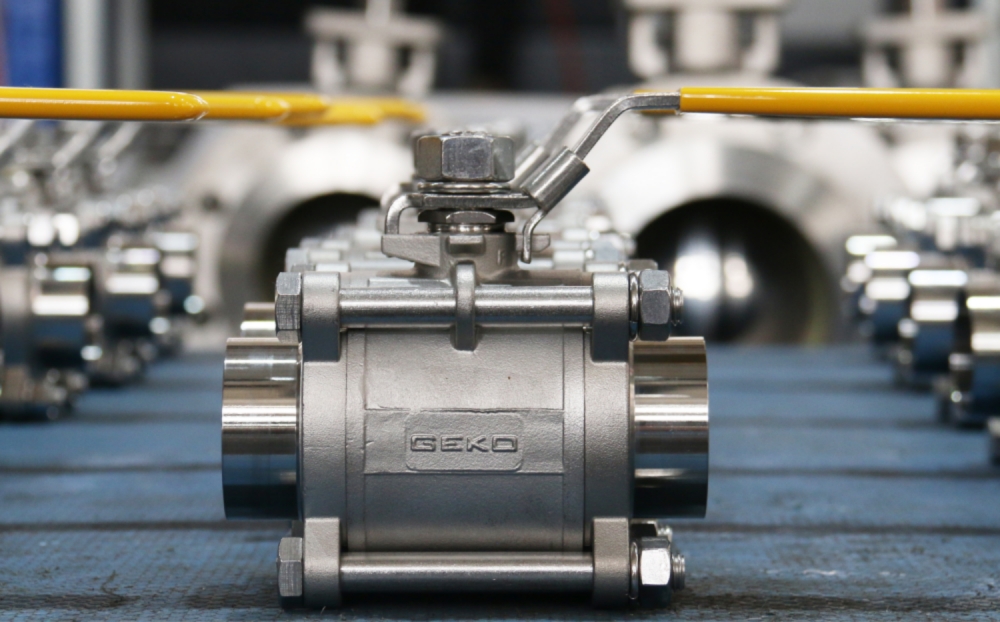

In the initially completed composite materials production lines of the Guotai Dacheng Carbon Fiber Project, a valve safety interlocking program based on meeting SIL2 safety levels was implemented. GEKO valves and controls , as required, provided the production line with 248 sets of dual solenoid valve configurations (one route for Safety Instrumented System (SIS), and another route for Distributed Control System (DCS) with zero-leakage pneumatic shutdown ball valves. The products obtained Chinese national patent and certifications including TUV-SIL3, TVU Low Emission, TVU API 607 Fireproof, CCC, and Ex NEPSI Explosion-proof, meeting all the project's requirements for high-standard key supporting equipment in international advanced production lines.

The zero-leakage pneumatic shutdown ball valve configured with dual solenoid valves exhibits several advantages in practical operating conditions:

1. **Redundant Control Path:**

- One solenoid valve is connected to the Safety Instrumented System (SIS), while the other is connected to the Distributed Control System (DCS), providing a redundant control path.

- In case of a failure in one system, the other system can still operate the valve, avoiding situations where a single control system failure renders the valve inoperable, thus enhancing system reliability and safety.

2. **Integration with DCS:**

- By integrating the pneumatic shutdown ball valve into the DCS, the valve's status can be monitored, allowing for real-time control of the valve's opening and closing.

- This integration enables more precise process control and coordinated operations.

3. **Real-time Alerts and Fault Indications:**

- The pneumatic shutdown ball valve provides real-time alarms and fault indications, aiding in the timely detection and resolution of issues and minimizing downtime.

4. **Zero-leakage Feature:**

- The zero-leakage characteristic ensures no media leakage when the valve is in the closed position, contributing to environmental protection, preventing resource waste, and improving process sealing and production efficiency.

5. **Tailored Design and Configuration:**

- GEKO designs and configures the dual solenoid valve system and its interaction with the integrated control system based on specific operational conditions and safety requirements.

- This results in more automated operations, reducing the need for manual intervention and enhancing overall operational efficiency and consistency.

In conclusion, this invention reduces risks, provides flexible integrated control options, ensures the stable operation and efficiency of the production process, and safeguards the safety of personnel and equipment.

Contact us: info@gekko-union.com

Read More