What Are You Looking For?

The GKV-9 Triple Offset Butterfly Valve offers two sealing designs: laminated metal and pure metal. It ensures over 50,000 maintenance-free cycles, meets API 607 and ISO 10497 fire test standards, complies with TA-LUFT and ISO 15848-1 fugitive emission regulations, and has passed the BS 6364 cryogenic test for reliable performance under extreme conditions.

|

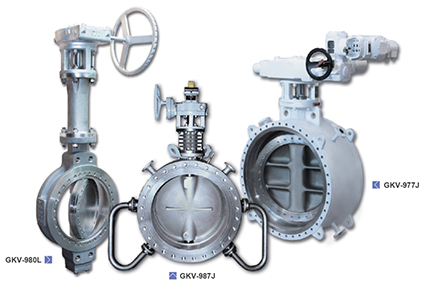

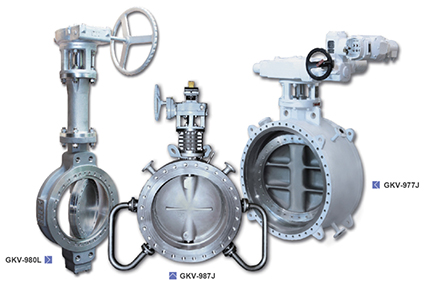

GKV-9 series three offset butterfly valve

|

|

|

Size Range 2"~160"(DN50~DN4000)

|

Body Materials Carbon steel (WCB, A105), stainless steel (CF8/CF8M, CF3/CF3M), alloy steel (F51,F22, WC6, WC9), duplex/super duplex (2205, 2507), nickel-based alloys (Inconel 625, Hastelloy, Monel 400), or special materials (Titanium, Zirconium, Tantalum). |

|

Temperature Range -320°F to 842°F(-196°C to 450°C) |

Maximum Allowable Operating Pressure ASME 150LB, 300LB, 600LB 900LB/ EN 1092 PN 10, 16, 25, 40, 63, 100, 150 |

|

Stem Materials 17-4PH, 410 Stainless Steel, XM-19 (Nitronic 50),stainless steel (410, 420, 431, 17-4PH, 316) or nickel-based alloys, optionally hardened or coated for extra strength and wear resistance |

Seat Materials Features laminated stainless steel with graphite, Stellite hard-faced alloys, or soft seals (PTFE, RPTFE, Viton, EPDM) depending on application.

|

|

Shut off Rating Zero Leakage

|

Disc Materials Stainless steel, duplex stainless steel, or nickel-based alloys, with optional hard-facing (Stellite, WC) or HVOF coating for wear and corrosion resistance. |

|

Design Standard API 609, ASME B16.34, ASME VIII, API 600 |

Flange Drilling ASME B16.5, ASME B16.47, EN 1092, ISO 7005 |

|

End Connections Wafer, Lug, Double Flanged |

Testing standard ISO 5208, EN12266-1, API 6D, API 598, BS 6755 |

|

Ports Full bore |

Connect Platform ISO5211, Bracket |

|

Face To Face AAPI 609, ASME B16.10, ISO 5752, EN 558 |

Applications Oil and gas, steam, power generation, refining, chemical processing |

GKV-9 Triple Offset Butterfly Valve

The triple-offset valve provides a bidirectional bubble tight shut-off . This geometry ensures that the disc seal contacts the body seat only at the final shut-off position without rubbing or galling, providing a torque generated resilient seal with sufficient “wedging”to ensure a uniform seal contact.

The body in Stellite 21 alloy for long life and easy maintance.

Design and construction accroding to international standards or customer specifications

- Offset 1: The shaft is offset behind the seat axis to allow complete sealing contact around the entire seat.

- Offset 2: The shaft centerline is offset from the pipe and valve which provides interference free opening and closing of the valve.

- Offset 3: The seat cone axis is offset from the shaft centerline to eliminate friction during closing and opening and to achieve uniform.

The low torque guarantees easy operation and the metal seat design allows

it to be applied in severe services. All parts are replaceable and in-line

maintenance is available.

Design specifications:

Body connection type: lug, wafer, flanged

Thickness: ASME B16.34

Face-to-face: API 609, ISO 5752

Pressure: ASME B16.34

Fire test: API607, ISO 10497

Pressure test: ISO 5208, API 598

Cryogenic: BS 6364

Explosion-proof: ATEX

Features of Triple Offset Butterfly Valve GKV-9 Series

There is almost no friction between the valve plate and the valve seat. The valve plate has two designs: metal interlayer seal and pure metal seal, thus it can work under temperature from -196℃ to 760℃.

The switch life can reach more than 50,000 times without adjustment.

Features:

• True triple offset geometry

• Fully bi-directional zero-leakage* shutoff

• Field replaceable metal seat

• Life cycle tested as a bubble-tight bi-directional valve

• Compliance and Specifications: TA-LUFT、ISO 1584-1、BS 6364

• Self-centering disc

• Available in a wide range of configurations: lug, short (ISO), and long pattern