What Are You Looking For?

Introduction

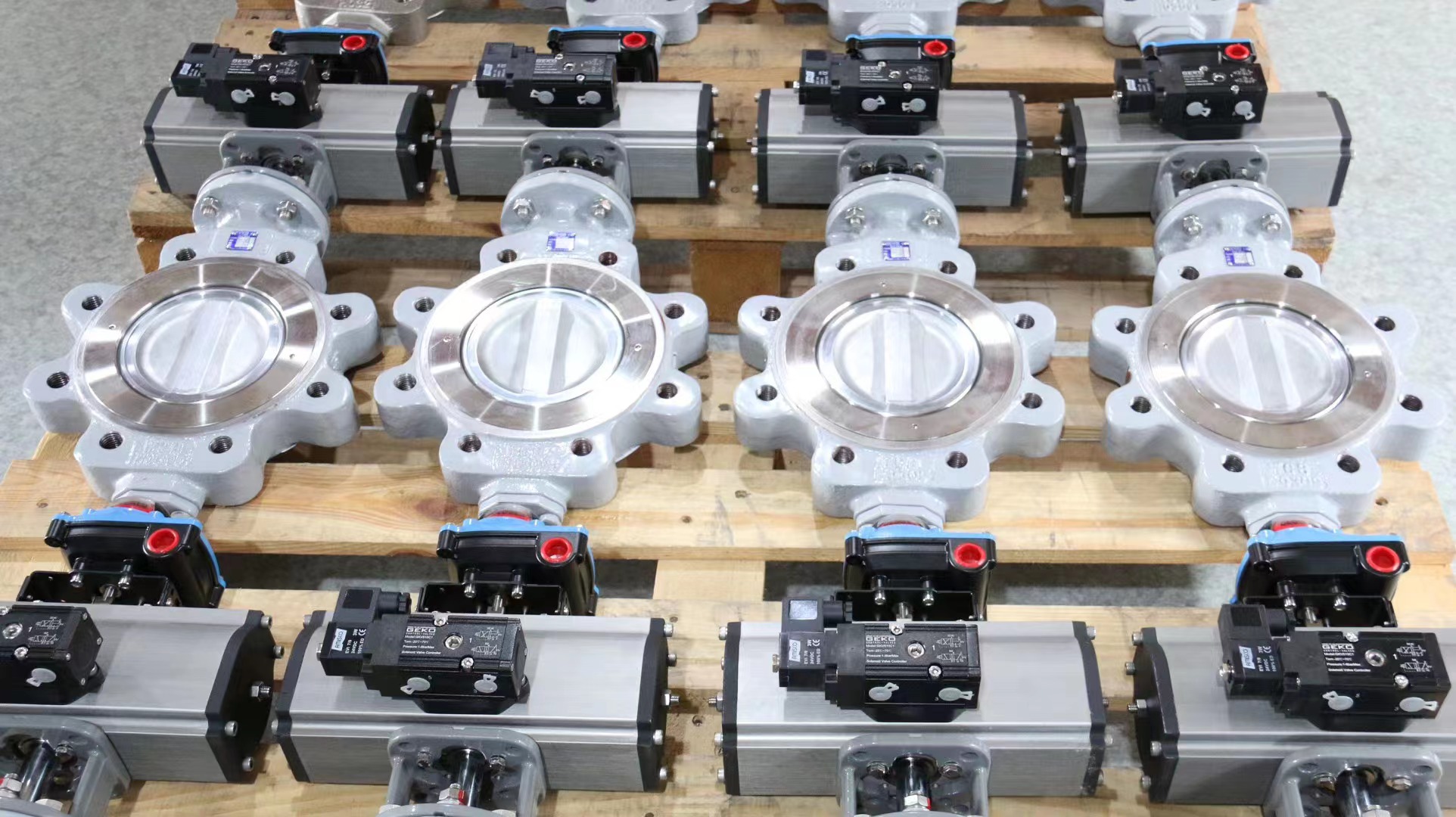

Butterfly valves play a crucial role in various industries, it also named / Rotary Valve / Butterfly Disc Valve / Butterfly Plate Valve /Butterfly Damper /Butterfly Control Valve /Rotary Disc Valve /Rotary Valve . They controlling the flow of liquids and gases. However, some users encounter durability issues with these valves, which can lead to operational problems and increased maintenance costs. In this article, we will explore the reasons behind butterfly valve durability problems and present solutions, all while promoting the GEKO brand as a reliable solution .

Common Durability Issues

Seal Degradation: One of the most common problems is the degradation of the valve's sealing components. Over time, the seals can wear out, leading to leaks and decreased valve performance. This issue can be caused by poor-quality materials or inadequate maintenance.

Corrosion: Butterfly valves exposed to corrosive substances can suffer from corrosion. Corrosion weakens the valve's structure, potentially causing leaks or valve failure. Subpar materials and improper coating are often the culprits.

High Temperatures and Pressure: Some butterfly valves are used in applications with extreme temperatures and pressures. Under such conditions, the valve materials may not withstand the stress, leading to deformation or failure.

GEKO Butterfly Valves : The Solution

When it comes to addressing durability issues in butterfly valves, the GEKO stands out as a reliable solution. Here's why:

Quality Materials: GEKO manufactures butterfly valves using high-quality materials, ensuring resistance to wear and corrosion. The use of premium materials extends the valve's lifespan and reduces the likelihood of seal degradation or structural issues.

Robust Design: GEKO's butterfly valves are designed to handle demanding conditions, including high temperatures and pressures. Their robust construction ensures reliable performance even in challenging environments.

Advanced Coatings: To combat corrosion, GEKO applies advanced coatings to its valves. These coatings provide an extra layer of protection, preventing corrosion-related problems.

Quality Assurance: GEKO implements strict quality control measures throughout the manufacturing process. Each valve undergoes rigorous testing to ensure it meets the highest industry standards, reducing the risk of defects.

Conclusion

Durability issues with butterfly valves can lead to operational headaches and increased costs. However, by choosing the GEKO , users can enjoy reliable and long-lasting butterfly valves that are engineered to withstand various challenges. Investing in high-quality butterfly valves not only ensures smooth operations but also contributes to the overall efficiency and safety of industrial processes. Choose GEKO for durable, high-performance butterfly valves that stand the test of time.