INTRODUCTION

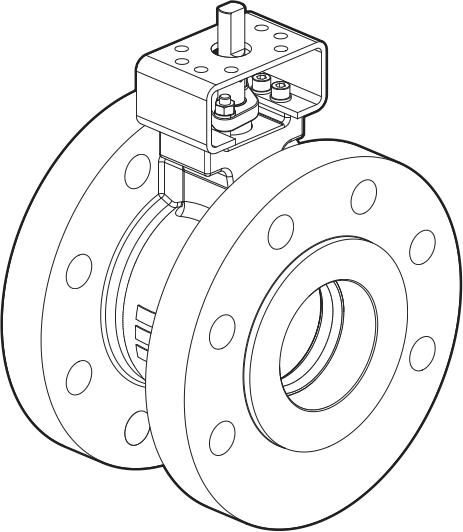

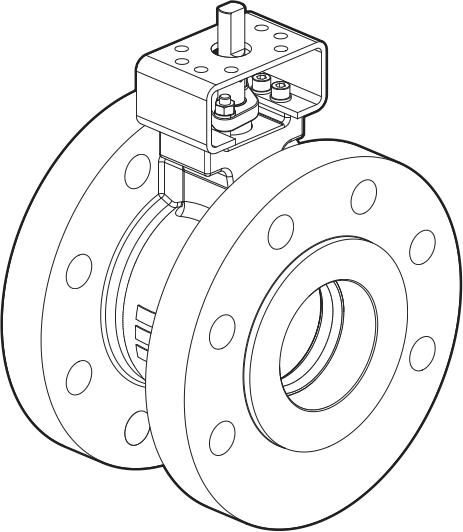

Information provided in this manual is for S19 segmented ball valves only. Specific instructions for non-standard materials of construction, temperature range, etc. should be referred to the factory.

This manual covers S19 valves in the following range:

- NPS 1 to 16 | DN 25 to 400

- ASME Class 150, 300, 600 | PN 10, 16, 25, 40

- Body Style: Flanged, Flangeless

Additional product information (such as application data,

engineering specifications, actuator selection, etc.) is available from your local Bray distributor or sales representative, or online at geko-union.com

The S19 segmented ball valve is designed per ASME B16.34.

Design and Function

-

Segmented Ball : The ball inside the valve has a V-shaped notch or segment, which provides a variable flow area as the valve is rotated.

-

Flow Control : The V-notch allows for a more linear flow characteristic, making these valves suitable for throttling applications.

-

Actuation : They can be operated manually or automated using electric, pneumatic, or hydraulic actuators.

-

Seating : They often use resilient seats made from materials such as PTFE or metal seats for higher temperatures and pressures.

Applications

-

Industries : Used in various industries such as chemical processing, water treatment, pulp and paper, and oil and gas.

-

Fluid Types : Suitable for liquids, gases, and slurries.

-

Flow Control : Ideal for applications requiring precise control of flow rate.

Advantages

-

Precise Control : The V-notch design offers superior flow control compared to standard ball valves.

-

Durability : Robust design suitable for high-pressure and high-temperature applications.

-

Versatility : Can handle a wide range of fluids, including abrasive and corrosive substances.

Maintenance and Operation

-

Maintenance : Generally low maintenance due to fewer moving parts.

-

Operation : Can be easily automated for remote operation and integration into control systems.

Selection Considerations

-

Material Compatibility : Ensure the valve materials are compatible with the fluid and operating conditions.

-

Size and Rating : Select appropriate valve size and pressure rating for the specific application.

-

Actuation Needs : Consider the type of actuator required based on the control system and operating environment.

Segmented ball valves are an excellent choice for applications requiring precise flow control and reliability under demanding conditions. info@geko-union.com