What Are You Looking For?

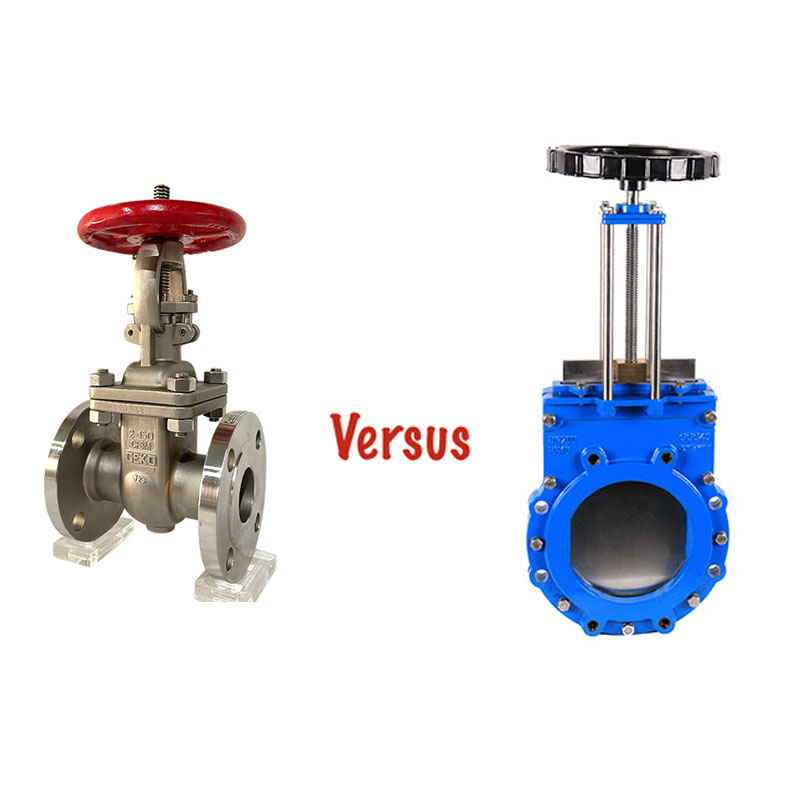

There are many types of gate valves, and knife gate valve is one of them, also called knife style gate valve. Depending on the type of structure, gate valves can be divided into flat gate valves and knife gate valves. According to the different connection methods, the knife gate valve can be divided into flange type, lug type and wafer type.

Compared with ordinary gate valve, the structure of knife gate valve is simple. It is small in size, flexible in operation and easy to install. It is more suitable for medium with high consistency and solid particles. As can be seen from the name, the knife gate valve mainly relies on the blade-shaped gate to cut off the medium. The gate has two sealing surfaces forming a wedge shape. The gate can be made into an integral rigid gate; it can also be made into an elastic gate that can produce a small amount of deformation and improve the sealing performance from the process. To sum up, the knife gate valve mainly highlights the following product advantages compared with ordinary gate valves:

The U-shaped gasket has a good sealing effect.

The full diameter design makes the medium passing ability strong. At the same time, under the condition of dirty medium, it is easy to install, disassemble and maintain, and the sealing part of the valve can be replaced without removing the valve, which makes the maintenance of the valve easier.

The gate with gate knife function has good gate breaking effect, can effectively cut off all kinds of sundries in the medium, and solve the leakage phenomenon after gate breaking of media containing blocks, particles and fibers.

The ultra-short structure length of the knife gate valve, small size, small flow resistance, light weight, material saving and small effective space occupation.

Although the price of bonneted knife gate valve is higher than that of ordinary gate valve, its good performance has been generally recognized by the market.

Mining, coal washing, iron and steel industry -- used for coal washing and washing pipelines, slag filtering pipelines, etc., ash discharge pipelines;

Purification device - used for waste water, mud, dirt and clarified water with suspended solids;

Paper industry - used for any concentration of pulp, material-water mixture;

Power station ash removal - used for ash slurry.

Before installing the knife gate valve, check the valve cavity and sealing surface and other parts, and no dirt or sand is allowed to adhere.

The bolts of each connecting part should be tightened evenly.

Check that the packing parts are required to be pressed tightly, not only to ensure the sealing performance of the packing, but also to ensure the flexible opening of the gate;

Before installing the valve, the user must check the valve model, connection size and pay attention to the flow direction of the medium to ensure the consistency with the valve requirements;

When installing the valve, the user must reserve the necessary space for the valve drive;

The wiring of the drive device must be carried out according to the circuit diagram;

The knife gate valve must be maintained regularly, and must not be collided and squeezed at will, so as not to affect the sealing.