What Are You Looking For?

Gas leakage in industrial applications poses significant safety risks and financial losses. Nitrogen (N2) gas, often used in various industries, can be particularly challenging to contain. To address this issue, engineers and valve manufacturers have developed an innovative solution: a GEKO gate valve with air-sealing nozzles. This article explores the technology behind this groundbreaking development and its potential to revolutionize industrial gas containment.

Challenges of Gas Leakage:

Gas leakage, especially in applications involving nitrogen gas, can have serious consequences. It can result in reduced system efficiency, environmental concerns, and, most importantly, pose health and safety hazards to personnel. Traditional gate valves, while effective in many respects, may not always provide the necessary sealing for gases like N2.

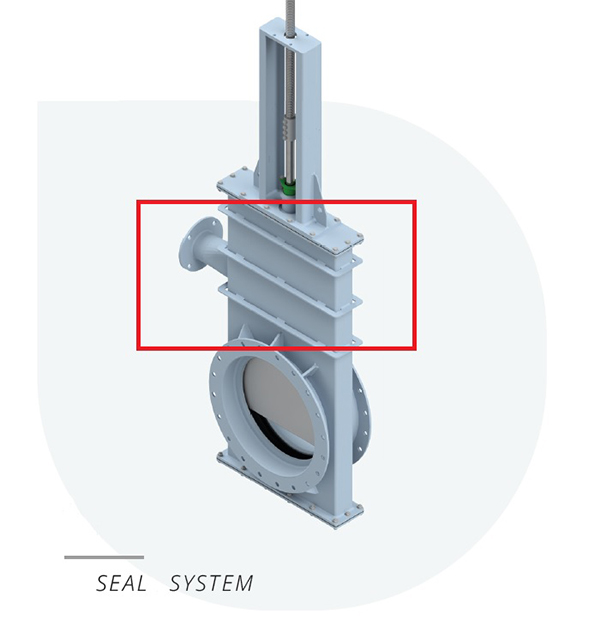

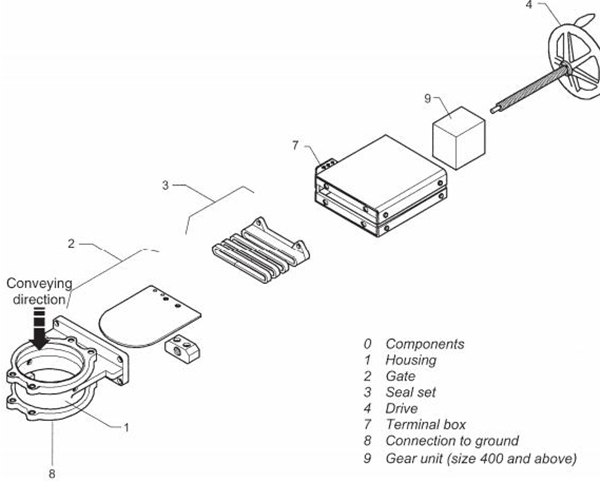

The GEKO gate valve with air-sealing nozzles is a novel solution designed to tackle the challenges of gas leakage. This innovative valve integrates specialized nozzles that inject a controlled flow of air into the sealing area when the valve is in a closed position. The key features and benefits of this technology include:

Enhanced Sealing: The introduction of air sealing nozzles significantly improves the sealing capabilities of the GEKO gate valve , especially when dealing with gases like N2. It ensures a reliable and hermetic seal, minimizing the risk of leakage.

Reduced Maintenance: By reducing or eliminating gas leakage, this technology decreases the need for frequent maintenance and repairs, saving both time and resources.

Safety and Environmental Benefits: The enhanced sealing reduces the risk of gas leaks, enhancing workplace safety and minimizing the environmental impact of N2 emissions.

Versatile Applications: This technology is suitable for a wide range of industrial applications, from chemical processing to oil and gas, and beyond.

Working Principle:

The GEKO gate valve with air-sealing nozzles operates as follows:

Closing the Valve: When the valve is closed, the air sealing nozzles are activated, directing a flow of air toward the sealing area.

Creating a Barrier: The injected air creates an additional barrier, preventing the gas (N2) from escaping through potential leakage points.

Hermetic Seal: The combined action of the valve's traditional sealing mechanisms and the air sealing nozzles ensures a hermetic seal, effectively containing the gas.

The GEKO gate valve with air sealing nozzles represents a remarkable advancement in industrial valve technology, specifically designed to combat gas leakage challenges associated with N2 and other gases. Its innovative approach to sealing has the potential to improve safety, efficiency, and environmental sustainability across various industrial sectors. By embracing this technology, industries can reduce the risks and costs associated with gas leakage, ultimately enhancing their operational integrity.

Please contact us for inquiry: info@geko-union.com